Using high tech against downtimes

The pellet plant of Energieversorgung Offenbach (EVO) in Germany is one source among many supplying customers with heat and energy. EVO processes 90,000 metric tons (approx. 100,000 short tons) of pellets per year and delivers them to the furnaces of private homes, businesses, and municipalities.

Challenge

In shift operations, seven days a week, the maintenance team at the Offenbach plant produces pellets from the wood chips and shavings. The material comes almost exclusively from the sawmills in the region. Producing pellets from the scrap wood takes one and sometimes several days. Primarily responsible for the variations is the moisture content of the incoming material.

How are pellets made?

Wood chips and shavings are delivered to the plant from surrounding saw mills. After initial chopping, the chips together with the shavings are dried before the material is chopped once more in a hammer mill. Adding starch and water creates a wood pulp to subsequently achieve the proper consistency for the familiar “worms.” The worm-like shape of the pellets is created in the presses. Afterwards, the warm wooden pellets are post-processed once more using a cooling system and screen and stored in a product silo, ready for shipping.

Lofty heights …

“Getting an overview of the machines means climbing a vertical ladder, 23 meters (75 feet) high, among other things,” says Andy Richter, the pellet plant’s operations manager. “That keeps you physically fit but entails risks. For instance, I check if the infeed conveyor is running, whether the blowers are properly transporting the moist air toward the outside, whether the drum is still operating the way it should, or motors are driving the operation. If everything is running like clockwork, I’m happy but know that these are snapshots that could change any minute.”

The players involved in the process …

Wood shredders, chain, belt, and screw conveyors, screen and loading equipment literally work hand in hand. It’s dusty, warm, and noisy in some places, and some areas call for caution. The demands made on the plant and the maintenance team are high. “A system that’s a potential troublemaker, as Andy Richter affectionately puts it, “is the flue gas fan of the biomass heating plant that in combination with a district heat connection ensures supply of the heat required for the drying process. If that system is down unexpectedly especially emission issues, fire hazards, and total failure must be counteracted quickly. What else keeps us on our toes? Some machine components that are insulated for noise protection reasons. They don’t exceed legal noise emission levels but we can’t hear if a machine is not doing well.”

Fire at the pellet plant …

That’s the nightmare of any employee at a pellet plant. The immediate risks of a burning dryer may be the spreading of the fire, smoke development, or damage to other machines at the plant. In July 2022, that became a harsh reality when a big dust of smoke formed above the plant. Thanks to the rapid reaction of the workforce, the source of the fire could be extinguished by the fire fighters.

Supported by a reliable service partner …

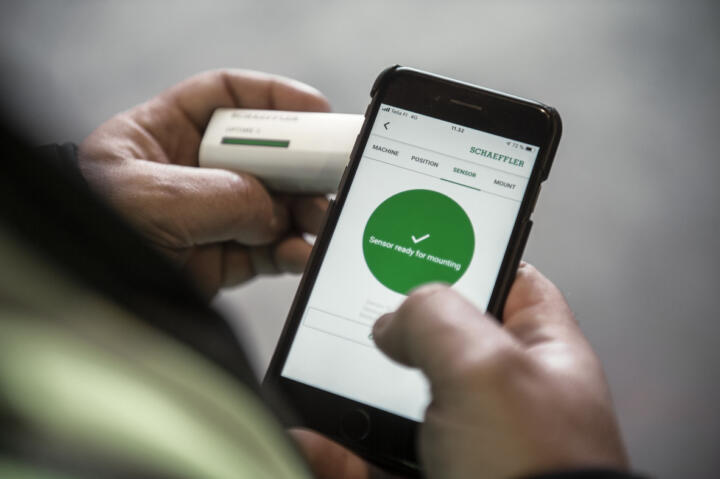

To minimize risks and facilitate planning of maintenance, the pellet plant is supported by Altmann, a certified service partner of Schaeffler’s and reliable constant. Altmann intervenes not only in the event of technical challenges but also provides predictive advice. To take the wind out of the sails of unplannable downtimes, the Altmann team arrived with a solution in its bags: Altmann recommended Schaeffler’s OPTIME CM condition monitoring solution to EVO to achieve greater predictability and reliability because OPTIME CM indicates condition results of the machines in an app. That enables the maintenance team to respond directly in the event of trouble. Climbing up the dryer is no longer a daily routine because the hard to access machine components are equipped with OPTIME sensors. If something’s wrong a warning is displayed in the app or on a computer at the control center.

How was the installation accomplished?

Following the installation of the gateways and wireless OPTIME sensors on motors and fans, Schaeffler still had to scan in the sensors via the OPTIME app, a process that was accomplished in next to no time. The data analyses are based on the physical models developed by Schaeffler, machine learning models, and the practical knowledge from decades of rolling bearing condition monitoring. A look at a smartphone or dashboard shows the maintenance team by means of colors which machines are suspected of trouble and names potential causes of faults such as bearing damage, misalignments, or imbalances.

Use case

A look at the app showed Andy Richter an increase in the acceleration characteristics on a flue gas fan that’s responsible for aspirating the flue gas resulting from the combustion process and to route it through the exhaust gas purification process before being released into the atmosphere. The readings exceeded the limit at a speed of 3,000 rotations per minute.

“With Schaeffler OPTIME CM, Altmann has provided us with a companion that reliably monitors our hard to access machines. The wireless monitoring system is not only cost-efficient but also easy to operate.”

Acting instead of reacting

The flue gas fan captured the maintenance team’s full attention for about three weeks because in the event of the fan’s unforeseen failure, the entire system must be shut down, resulting in downtime of around one day. All the indications pointed to a case of bearing damage. That prewarned and prepared the maintenance team. The bearing to be exchanged was on hand and replaced as planned.

How OPTIME CM works

The sensors monitor the machines and equipment at the customer’s site. The gateway receives the data from the sensors and transmits them to the Schaeffler cloud. OPTIME CM automatically detects faults, sets off corresponding alarms, and provides information about potential causes of failures. Expert knowledge of condition monitoring is not required because it’s already integrated in OPTIME CM in the form of Schaeffler’s know-how. OPTIME CM has won numerous awards since its market launch in 2021.

Further details on OPTIME CM wireless condition monitoring can be found here.