Sustainable thinking from scratch

The global industry depends on massive amounts of raw-material and energy input while having to avoid waste, save water, reduce carbon equivalent emissions*, and more to achieve the Paris Climate Goals. So, what needs to be done? The answer is that stepping up circular thinking is one option. Right from the beginning, products must be designed for conserving resources, easier repairability, and recycling of materials.

CO₂e = carbon dioxide equivalent

CO₂e (carbon dioxide equivalent) is a unit of measurement used to standardize the climate impact of various greenhouse gases. The global warming potential of a gas is related to that of CO₂. This allows methane, nitrous oxide etc. to be compared. CO₂e is central to climate balances, carbon footprints and emission targets.

One of the documents underpinning this proposition is the Global Circularity Gap Report showing that if the global economy’s supply chains were consistently designed for circularity more than 40 percent of global carbon equivalent emissions could be cut. That, however, requires rethinking in terms of materials, supply chains, and technologies across a product’s entire life cycle – from the first design sketch to material recycling.

“Sustainability must be put into real-world practice,” says Kathrin Ebner, who leads a project in the area of product sustainability at motion technology company Schaeffler. “Developers must ask themselves as early as at the concept idea stage: How can I conserve energy and resources? How can this product be reused and recycled at the end of its life?” In other words, thinking sustainability from scratch.

“The objective is to not only design individual projects for greater sustainability but to anchor that mindset in the entire organization.”

Development teams need a wealth of data

Knowledge is power. That applies to product development as well. Will I design a housing using plastics or aluminum? What makes more sense? What strikes a balance between environmental compatibility and costs? At Schaeffler, product developers have been supported in answering those questions by extensive material know-how, for instance on eco design, for a long time. Responsible for that effort is the Sustainable Products & Advanced Materials department. It is the central interface for and driver of strategic innovation projects. It analyzes the EU’s requirements and imbues the sustainability strategy with life.

100 percent

That’s the recycling rate for production waste at eight Schaeffler locations worldwide.

“Our job is to facilitate the availability of information. Stored in our material supplier database are material-related data of many of our suppliers including the associated carbon equivalent footprints, and, going forward, the content of recycled materials will be as well,” explains Kathrin Ebner, “Since 2021, every developer around the world has been able to log into that database. We feed it and additionally support it with calculations and hot-spot analyses.”

To enable every development team at Schaeffler to fully use the available opportunities for design and material selections in the future, Schaeffler in interdisciplinary teams is working on various methods and tools that can be used across the entire Group. Sabine Adrian, Environmental, Social, and Governance (ESG) Strategy Professional, is responsible for the circular economy strategy and describes the strategic approach as follows: “One of our goals is to anchor requirements, actions, and criteria concerning product sustainability in the development process from day one. We want to get away from case-by-case decisions and move toward clear structures so that sustainability can naturally be included in the thinking process for any new product.”

An interdisciplinary team is part of the project. Experts in sustainability, governance, process architecture, circular economy, purchasing, and product development are working together on solutions. An aspect of particular importance to Kathrin Ebner is to make decisions about those solutions as early as possible. “In the past, it was about costs and performance, today, sustainability is added as another criterion. The earlier environmental criteria are considered the easier it becomes to consistently implement them – and to ultimately bring to market products that conserve more resources and are fit for the future. Not as add-on tasks but as part of the DNA.”

“We need to broaden our perspective,” stresses Kathrin Ebner. “We’ve been talking about design for environment and circular business models enabling us to reuse materials for many years, but – going forward – we must do that with much greater intensity. That also means creating a new awareness about sustainability with everyone involved in product development.”

How Schaeffler improves its environmental performance

The green bearing cage

Although the share of the cage in the total weight of a rolling bearing is typically less than ten percent it can measurably help reduce the carbon equivalent footprint. A team at Schaeffler led by project manager Alfred Hock demonstrated that. For producing the cages, the engineers used bio-based plastics (polyamides), thereby reducing the carbon equivalent emissions by up to 90 percent – while retaining the bearing’s good mechanical properties and even increasing its service life. The calculated performance gain amounts to 120 percent, plus the reliable performance of the alternative material up to 120 degrees centigrade (248 degrees Fahrenheit) was demonstrated in component tests. The first customers from the automotive sector have expressed interest in the product.

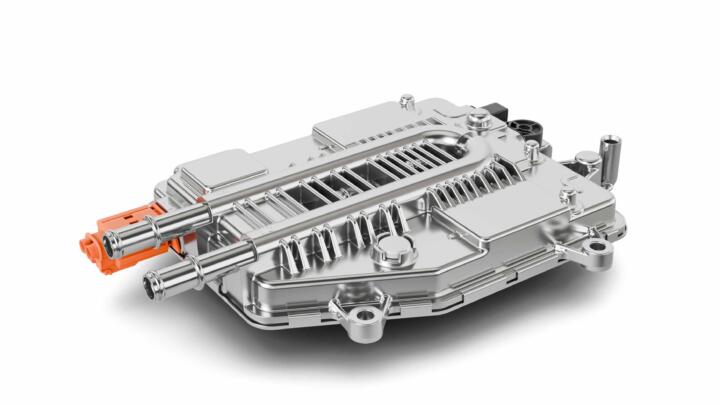

Avoiding electronic waste

The industry would like to avoid as much electronic waste as possible. In the EU’s EECONE project, Schaeffler, in a consortium with partners from the business community and academia, is showing how that can be done. Power electronics such as inverters, on-board chargers, or DCDC converters are supposed to become easier to repair and recyclable by means of clever environmental design. “Obviously, our objective with this project, as well, is to reduce our carbon footprint,” says Schaeffler’s project manager Olivia Belorgeot.

The objective is an ambitious one: 25 percent less electronic waste compared to the current generation. Tests of the inverter have shown that manual dismantling is possible in the space of 15 minutes – with a 96-percent recovery rate. To reduce the time needed for dismantling, adhesion-bonded components should be avoided.

More complex high-voltage boxes are another example of making modules exchangeable, optimizing connections, and making sealing agents easier to dissolve. All that is to be fed into new environmental design guidelines – for more circular economy content in vehicles.

Considering environmental impact

At Schaeffler, so-called life cycle analyses (LCAs) serve as a key tool for sustainability accounting of products, particularly considering carbon equivalent accounting by means of the carbon equivalent footprint. LCAs are prepared to calculate the environmental impact of products due to materials and manufacturing. They include an analysis of the supply chain and processes, thus enabling the identification of suitable reduction actions for the carbon equivalent footprint of Schaeffler’s products.