The measure of all things

Eight minutes before the next subway train arrives. Two kilograms (4.4 lbs.) of apples in your shopping bag. 500 meters (1,640 feet) before reaching your destination. Numbers are our constant companions – they’re part of timetables, recipes, and fitness apps. There’s a silent order behind that self-evidence: standardized units that also provide a reliable foundation for technical progress. In the academic world, the metric system that over time was extended into the “International System of Units” (SI) gained global acceptance. Even though as is commonly known, in countries like the United States, the United Kingdom, or Canada, Anglo-American measurement units such as miles, gallons, or pounds are typically used in everyday life, people in science and technology largely think in terms of metric units. NASA calculates in meters as well.

How everything began

Even the ancient Egyptians used to work with units of measurement: Their granite royal cubit rod, just under 52 centimeters (20 inches) long, served as the standard for building pyramids. Measures for lengths and weights were created in Mesopotamia, Greece, and Rome as well. Yet for centuries the system would remain patchwork – in the Medieval Age, a “foot” could vary from one city to the next and in Naples, the weight of a “pound” would differ from that of a pound in Cologne. Trade and science suffered from that chaos.

The French Revolution resulted in a fundamental gamechanger. In 1791, the Academy of Sciences defined the meter as the ten millionth part of the meridian length from the pole to the equator and as early as in 1795, France introduced a decimal system of measurements: meters, kilograms, liters. These units were no longer tied to bodily dimensions or arbitrary royal ones. The first primary platin standards emerged shortly afterwards – yet international implementation continued to be difficult.

In the wake of industrialization and growing world trade, the pressure on binding standards kept growing. Finally, on May 20, 1875, 17 countries signed the Metric Convention, creating the “International Bureau of Weights and Measures” (BIPM) in Sèvres near Paris – laying the foundation for the worldwide system of units that has been supporting science, technology, and everyday life until today.

The signatories were Argentina, Austria-Hungary, Belgium, Brazil, Denmark, France, Germany, Italy, Peru, Portugal, Russia, Spain, Sweden and Norway, Switzerland, the Ottoman Empire, the United States, and Venezuela.

A kilo is a kilo – or maybe not?

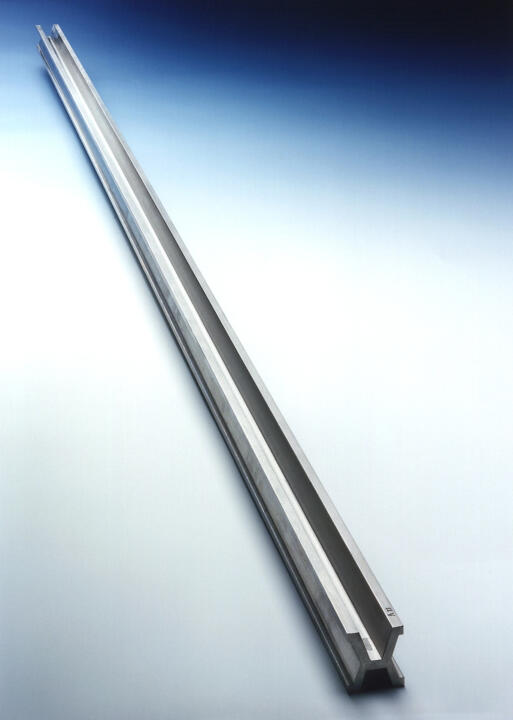

A decisive move followed in the 20th century when the standard physical measurements were replaced step by step by definitions based on natural constants. Since 1967 a second has been oriented to the oscillations of cesium thanks to the time measurement using atomic clocks. Putting it more precisely, the second refers to a defined number of oscillations in the electron shell of the cesium atom, the so-called clock transition. A meter, since 1983, has been oriented to the speed of light. A meter is obtained by dividing the distance that light in a vacuum travels in one second by 299,792,458. Until 1983, that unit was still defined by a piece of metal too – the so-called standard meter.

Dr. Dr. Jens Simon, Head of Public Relations at Physikalisch-Technische Bundesanstalt (PTB), the German National Metrology Institute, in Braunschweig, provides a cogent description of why the new definitions were necessary: “As nice and valuable and vivid an embodied gauge like the standard meter is, a closer look does reveal a range of issues. Temperature alone changes its length, while gravitation, depending on how it’s being held, distorts its shape, and its utilization in laboratory settings leaves signs of wear. Finally, one object alone that everything refers to is not enough. It’s necessary to produce and distribute copies of it that are as identical as possible. Plus, measures of length are not only required in the range of a meter but anywhere on the scale of lengths between the microcosm and macrocosm. Just like a kilometer or even astronomical distances, a nanometer or femtometer cannot be measured by a standard meter. These issues can only be overcome by abandoning the embodiment of the measure and replacing it by something that per se is unchangeable and valid on the entire scale of the unit: i.e., natural constants, in other words unchangeable characteristics of nature.”

Finally, on May 20, 2019, the International System of Units (SI) achieved its so far greatest breakthrough: basic units from the kilogram to the mol were redefined, strictly based on natural constants such as speed of light or the smallest possible amount of electrical charging.

The example of the kilogram makes this particularly tangible: Up until 2019, it depended on a metal cylinder made of platinum-iridium deposited in a safe in Paris. This “prototype kilogram” lost tiny fractions of its mass over decades – posing a problem for precision research and high tech. Today, the kilogram is based on the so-called Planck constant, an unshakable magnitude of nature. Be it in a laboratory in Berlin or a factory in Seoul: a kilogram is always the same and always will be.

Why are precise, classifiable readings so important in a globalized world?

From the nanostructure of a material to the component geometry in the range of meters – “tomorrow” talked to Tim Hosenfeldt, Head of Central Technologies at Schaeffler, about measuring technology, precision, and international standards – the cornerstones for quality, safety, and innovation in global supply chains. 3 questions for Tim Hosenfeldt.

“Think big” or “small, but exquisite” – what measuring worlds do you find to be more exciting?

For me, measurements across different scales are especially fascinating: They make it possible to comprehensively capture material properties – from the composition and structure in the nanometer range to the microstructure and the quality of the surfaces to the resulting component geometries and functionally relevant properties. That creates a holistic understanding of the correlations between the input material, manufacturing process, material properties, and component performance.

How important is extreme accuracy in industry today – and where does it make the decisive difference?

Extreme accuracy is indispensable for industry today. It’s the basis for quality, safety, efficient workflows, and new technologies – and it makes the decisive difference in practically all areas. Even the minutest variations in the micrometer range can cause problems with highly complex components in sectors like automotive, medical device technology, or aviation. Only utmost precision ensures that each component reliably functions, is durable, and corresponds to exacting requirements. Accuracy is key in terms of safety as well. Especially in safety-critical applications, such as in aircraft, vehicles, or medical devices, precision manufacturing prevents dangerous defects and minimizes risks.

„Precision pays off directly: It reduces scrap, avoids cost-intensive rework, and saves material.“

Precision pays off directly: It reduces scrap, avoids cost-intensive rework, and saves material. Schaeffler’s core competencies are putting in the right material into a reliable process in the right quantity in the right place with the right functionality in the best ratio between performance capacity, costs, and sustainability. In a globalized industry, precise, standardized measures ensure that components and systems from different countries and plants interact without any problems. That makes global supply chains flexible and reliable.

Precision, not least, is the prerequisite for innovation. Increasingly sophisticated technologies such as electric mobility, robotics, or digitalization call for maximum manufacturing accuracy and modern measuring technology – that’s the only way in which these developments are possible. Extreme accuracy is the key to reliable, safe, and innovative products. It strengthens industry’s competitiveness and pays off directly by increasing economy and customer satisfaction.

You mentioned supply chains: What role do international units and standards play in a corporation with global operations and highly complex supply chains?

In today’s globalized economy, international units and standards are indispensable. They serve as a common operating system that makes companies, technology, and trade compatible worldwide. Standards such as the SI system of units, ISO and IEC standards provide a uniform language in manufacturing and trade and prevent dangerous misunderstandings – like, for instance, the one in 1999 during the NASA Climate Orbiter mission (see info box) that failed due to unit-related errors.

This is what happens in the case of differences in standards

NASA’s Mars Climate Orbiter mission in 1999 failed due to a critical error in converting units. The NASA flight control team was working in metric units (Newton seconds for thrust) while contractor Lockheed Martin provided the engine data in Anglo-American units (pound force seconds).

Since the software mismatched both units, the navigation control center committed a calculation error for the position of the space probe. Consequently, the spacecraft entered Mars’ atmosphere in a position that was far too low, came dangerously close to Mars’ surface, and was destroyed.

Companies benefit from globally assured product quality and comparable test standards. That creates transparency and trust along complex supply chains. Additionally, identical standards reduce costs by eliminating redundant tests or complex customizations, and by clearly defining interfaces. Moreover, many international standards have been fed into national laws, which facilitates compliance with statutory requirements. In addition, they promote innovation and interoperability by ensuring the compatibility of machines, IT systems, and data formats.

Our mechatronics products show how crucial international units and standards are for a complex, world-spanning supply chain. To ensure that components smoothly fit together in a total system – for instance, in the automotive industry or in mechanical engineering – global standards for measures, materials, and interfaces are indispensable. ISO standards such as ISO 2768 for tolerances ensure that components from different regions are compatible. Standardized screws and fasteners according to ISO or DIN guarantee global exchange. Additionally, standardized processes in quality management, e.g., according to IATF 16949, consistently assure high standards with suppliers around the globe. ISO standards and UNECE provisions in environmental and safety management create comparability and legal certainty.

Another central argument is error avoidance: In automotive engineering, the utilization of SI units and the metric system is mandatory because differences in measuring units could cause considerable quality and safety risks. Uniform provisions prevent such misunderstandings and errors. Moreover, standardization means efficiency and economic benefits: standardized test procedures reduce the diversity of variants, cut warehousing costs, and avoid unnecessary multiple testing.

Crises such as the 2021 and 2023 semiconductor shortages clearly show how important standards are for industrial flexibility. Only when suppliers around the world manufacture according to the same standards can they stand in for each other and back up the supply chains.

Consequently, international units and standards are a key success factor for corporations with global supply chains. They create efficiency, comparability, and trust – while forming the foundation for smooth, secure, and innovative manufacturing worldwide.