All lights switched to green??

Does only the type of drive determine whether or not a car is carbon-neutral? In other words, a vehicle with an IC engine is a polluter and an electric car merits distinction as a product of high environmental value? Right? Wrong? Or, as is often the case, is the truth somewhere in between? In fact, electric cars do not emit any pollutants on the road, but they do consume energy. And this means that in the current electricity mix in most countries, emissions are generated elsewhere, for instance at coal- or gas-fired power stations. The energy chain plays a key role in the environmental assessment of electric vehicles – not only on the road, but as early as in production, because that’s where the environmental footprint of e-cars is worse than that of cars with IC engines. What’s more, the electric motor and the battery require special raw materials and their extraction causes environmental damage. On the inside of these fold-out pages, we’ll take a look at energy and supply chains.

One goal, many factors

For CO2 emissions to truly decrease significantly, a lot more has to happen than switching from IC engines to electric powertrains.

Here are some facts and figures along the energy, supply and manufacturing chains.

Renewable energies

Facts and figures

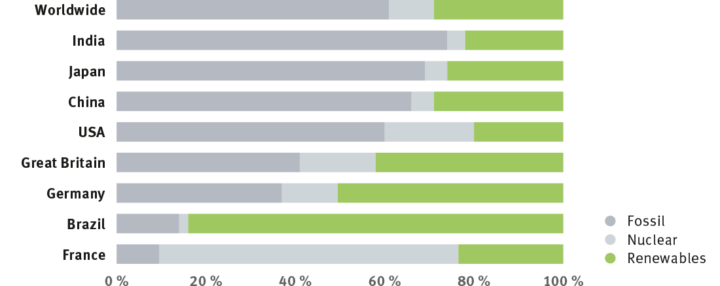

Electricity mix

This is how electric power is produced in the world

Conventional power stations

66 g CO2/km

(106 g/mi) is indirectly emitted by an e-car with an average consumption of 18 kWh/100 km (3.45 mi/kWh) in view of the current electricity mix in Germany. IC engine: 166 g CO2/km (267 g/mi) at 6.2 l/100 km (38 mi/gal). (Source: German Federal Ministry of Economics and Energy)

32 % less emissions

could be caused during charging processes if e-cars were preferably charged whenever a surplus of green electricity is being produced. However, this requires smart grids like those that Norway and Sweden have, for example. (Source: Dominik Husarek, Siemens)

Gasoline or electricity?

Volvo has compared the carbon footprints of the gasoline-powered Volvo XC40 and its all-electric sibling across their entire lifecycles, incl. 200,000 km (125,000 miles) of distance traveled, and come up with some interesting figures.

Raw materials

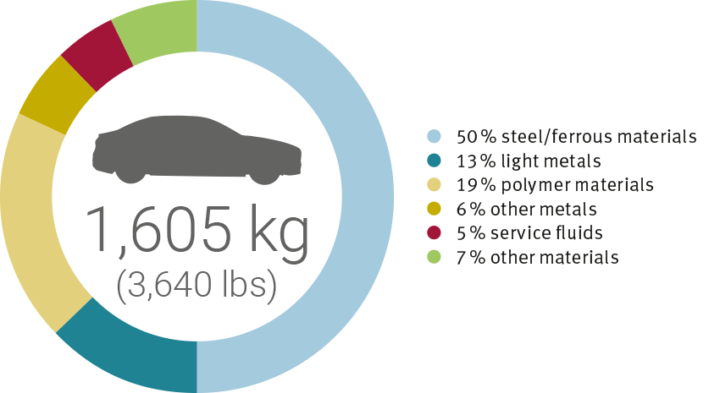

What does a car consist of?

17,000 l of fuel

are consumed by an average car with a gasoline engine during its entire useful life. This equates to 12,500 kg (27,560 lbs) of mass to be moved. In an electric vehicle, this is contrasted by 160 kg (353 lbs) of metallic raw materials for the battery. (Source: transportenvironment.org)

Lithium-ion batteries

Each of the lithium-ion battery cells consists of two electrodes, a separator and liquid electrolytes. The electrodes consist of graphite, lithium, nickel, manganese and cobalt. Electrochemical batteries with comparable properties are not currently producible without these raw materials. These quantities of the raw materials are installed in a 58 kwh-battery (385 kg/849 lbs) of a VW ID.3. Especially graphite, cobalt and lithium are deemed to be problematic.

Production

Transportation emissions

Grams of CO2 equivalent per metric ton-km

8,500 passenger cars

can be loaded onto the world’s largest car carrier vessels of Höegh Autoliners in Norway. The ships are equipped with fuel-saving technology that reduces the equivalent unit of CO2 emissions per car by 50 percent compared to standard car carrier vessels. In 2021, Höegh deployed a vessel powered by biofuel that even cuts CO2 emissions by 90 percent. The remaining 10 % was offset by the shipping company. For 2040, Höegh is targeting “zero emissions.”

Schaeffler climate goal: CO2 neutral production from 2030 on

Suppliers like Schaeffler make a significant contribution on the road toward climate-neutral mobility. Not only with energy-efficient products but with their CO2-neutral production as well, which Schaeffler is aiming for by 2030, worldwide. To achieve this goal, the company has set its sights on its entire value chain, incl. raw materials, packaging and logistics, is increasingly focused on a circular economy and prepares life cycle assessments (LCAs). With LCAs, the environmental impact of individual products can be made transparent across their entire lifecycle and improvement actions derived. Achieving this goal continues to be a challenge. As of 2020, Schaeffler mastered 26 percent of the way toward climate-neutral production, among other things, by exclusively purchasing green electricity in Germany, Austria, the Slovak Republic, Mexico, Spain and the United Kingdom, with plans to do so at all locations from 2024 on.

Vehicle utilization

64 %

of the energy used to propel an e-car is actually transferred to the road – three times more than in the case of cars with IC engines, which have an energy efficiency of 20%. Ranging in between are hydrogen cars (27 %).

Car travel needs to catch up

Unlike sectors such as manufacturing and construction, no CO2 has been saved in automobile usage since 1990. The opposite is true: CO2 emissions have gone up. Now the EU is taking countermeasures. Stricter emission standards for passenger cars and light trucks are supposed to accelerate the transition to zero-emissions mobility. From 2030 on, the average annual emissions of new vehicles have to be 55 % lower and from 2035 on by 100 % lower than in 2021. In the final analysis, 60 % of all new cars will have to be emission-free from 2030 on and 100 % of them from 2035 on, according to the EU.

Reservations against e-cars

Survey of persons 16 years and older in Germany

approx. 18 %

That’s how much the electricity requirement in Europe would increase if all 325 million existing passenger cars were electrified and charged regularly. (Source: in-house projection)

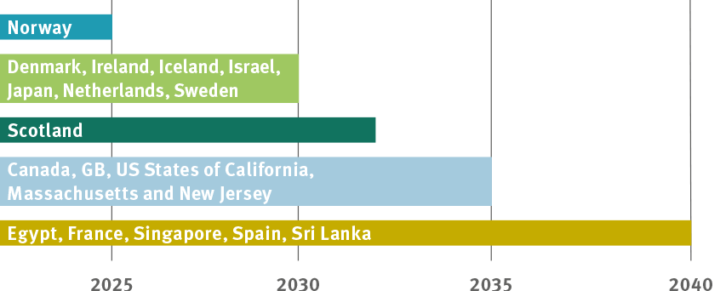

Bans on sales of diesel and gasoline cars

Plans by individual countries/regions

Recycling

Shredding instead of smelting

At the end of January 2021, the VW Group launched a pilot plant in Salzgitter for recycling high-voltage batteries from electric cars. Instead of the energy-intensive (more than 1,000 °C / 1,800 °F) and problematic smelting technology (the incineration of the electrolytes produces fluorine gases) VW uses a combination of shredding and subsequent chemical extraction of the recyclables. In a first stage, up to 1,500 metric tons (1,650 short tons) per year are supposed to be recycled. “Subsequently, the system will be scalable to larger quantities with further optimized processes,” according to the Group. Recycling is focused particularly on elements such as lithium, nickel, cobalt, manganese and aluminum, but also on plastics. VW is targeting a recycling rate of 90 %.

92.9 %

of the parts or materials of a car are recycled EU-wide. (Source: Eurostat 2020)

10–12 years

is the potential second life of a discarded traction battery that will still have a storage capacity of 70–80 %, for use in a forklift truck or as a storage device for a domestic solar system, for example. (Source: ADAC)