Virtual testing for tough reality

Houston, we’ve had a problem here: The astronauts of the Apollo 13 lunar mission that spectacularly failed in April 1970 more than likely owed their life to “mirroring technology” as NASA used to call the method back then. The U.S. National Aeronautics and Space Administration had been conducting research relating to complex simulation models for testing space technology since the 1960s. When an oxygen tank exploded on board of Apollo 13 on the way to the Moon and the crew of the crippled craft escaped into the Aquarius module that had been intended for the lunar landing the people at the mission control center in Houston developed a rescue plan that was also based on 15 computer-controlled models simulating the conditions on board of the damaged spacecraft.

Today, “mirroring technology” is referred to as digital twin technology and far more complex. However, thanks to increasingly powerful computers, the technology has long arrived in the terrestrial manufacturing world on a large scale. Products, processes, locations and, in medicine, even people: the twin graph serves to mirror procedures, objects or subjects from the physical world. In the virtual world, the digital duplicate can be used to run tests, simulate probable behavior of materials and objects under a wide variety of conditions and to gather and analyze mammoth amounts of data in the process. That accelerates developments and transformation processes.

Fast-paced developments are the order of the day more than ever before especially in the automotive industry. Be it electrification, automation, or connectivity – OEMs or suppliers that don’t want to be left behind in the mobility transformation race need to develop innovations to the level of marketability as quickly as possible.

Sensing deficits before they become reality

Digital twins truly are turbochargers in development processes, not least because they help expose problem areas at an early stage. “The earlier you find issues, the easier it is to solve them,” says Guido Bairati in an article for the global engineering association SAE. The Italian is managing director at VI-grade, a simulation specialist with worldwide activities. Thanks to increasingly realistic simulation, some of Bairati’s customers from the automotive sector are said to have reached a point at which the first physically tangible prototype already corresponds to the level of a pre-production model.

“A month of real-world testing can be done in less than a week in the simulator”

Louis Jamail, supervisor of the simulator and core methods group at Ford

In the case of complex and costly developments like those in automotive engineering, tests save not only time but also costs. Volvo, for instance, claims to have cut the development cycle of their current SUV platform in half by using modern simulation technologies. Simulators enable engineers to use their digital twins for testing and validating hundreds of thousands of “what if” scenarios occurring during a vehicle development project – a breadth that would not be feasible with real-world test vehicles. “A month of real-world testing can be done in less than a week in the simulator,” says Louis Jamail, supervisor of the simulator and core methods group at Ford in the United States. Why build ten prototypes of which nine don’t work the way you want them to? “We save money with each one-off prototype we don’t have to create,” emphasizes Jamail. “The savings in both time and money far outweighs the millions spent on the simulator,” he adds.

Highly complex simulator technology

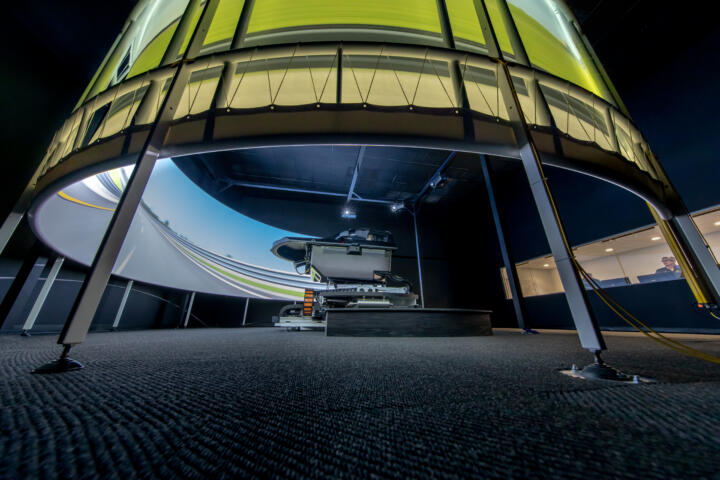

VI-grade’s high-tech system at Ford’s development center in Dearborn in the United States resembles a flight simulator except that instead of a jet aircraft cockpit a car body that’s been cut off behind the driver’s seat has been installed on the complex electrohydraulic motion system. The semicircular screen that has spread in front of the vehicle body evokes associations with a game console, but an XXL-size one. The test engineers’ control center packed with monitors is located behind a large pane in the rear section of the simulator. Systems like these breathe life into the computer-developed digital vehicle twins, causing them to rock, shake, brake and accelerate.

Operating several driving simulators has become standard practice for automakers, not only in research and development settings. Such virtual reality driving simulators can also be used for testing prototypes that are still in the virtual stage on potential customers. Their feedback can immediately be considered in the design and manufacturing process as well and consequently contribute to the gain in quality and time for the total development process.

On the road toward the industrial metaverse

The virtual twin of a vehicle can be used in all kinds of conceivable test simulations not only instead of the physical prototype but in all modeled production processes. Can the body be assembled as planned? How will planned tolerances affect the look? Based on questions like these, production experts can evaluate the design and development of a new car model at an early stage of the creation process according to production criteria and initiate necessary modifications.

Ideally, digital product twins will become part of a comprehensive industrial metaverse. One of the prerequisites for that to happen is that data must be readable and suitable for interpretation across system and, ideally, even corporate boundaries. This kind of interoperability can only be achieved by a so-called asset administration shell (AAS). In it, requirements for modeling of components in the digital world are defined just like release restrictions because no business would like to divulge all its valuable know-how. Digital twins cannot be interlinked without such standards, but interlinking is important. “Otherwise, we cannot achieve our goal of successively arriving at a holistic data model of a product’s entire lifecycle,” says Rainer Eidloth, Senior Vice President Engineering IT at Schaeffler (see also related interview).

Virtual anticipation of reality

Companies around the globe are working on such complex digital twin worlds. Volkswagen is a case in point. The Group’s production network includes 118 locations, worldwide. Many of them are already finding themselves in a virtual world. Volkswagen’s Audi brand uses the combination of digital twins and virtual reality to realistically visualize what the planned production of a new model is going to look like later as a whole. Andrés Kohler, Head of Virtual Assembly Planning at Audi, says, “I’m always fascinated all over again the moment we put on the VR glasses and meet our colleagues as avatars in the virtual world. First, we build our new Audi there or look at a computer-generated avatar and how it applies as a real-time simulation. And when necessary, while we’re in there together, we discuss and optimize the sequences and the workplace environment, like how to set up materials or what tools are needed.”

Insights into the virtual worlds are also intended to enable the Group’s production managers to compare the processes at different plants with each other. If the engineers’ quest for a good solution is successful at another plant, they can adopt the idea for their own planning process. That can help accelerate the migration of innovations into production as well.

The electric mobility challenge

Aside from its use in manufacturing and vehicle development, the digital twin is right on cue for new tasks in the age of electric mobility, where engineers are faced with all-new challenges after more than 130 years of working with internal combustion engines (ICEs). Powertrain testing is a case in point because electric motors are far more dynamic than ICEs. They operate in a more elastic range and require new dyno testing technology. As a result, model-based validation is gaining in importance. Another key aspect is charging management, which entails a reciprocal challenge. Since the providers of charging stations need to prepare for serving all the vehicles in the marketplace, testing all those models hardly seems to be an efficient approach. Digital twins instead of real automobiles can do the job more efficiently. Conversely, automakers need to manage the task of designing their products for a wide variety of charging systems and standards around the globe. That’s another area in which extensive physical tests could be accomplished only with a major investment of time and money. Instead, virtual models deliver a much faster return on investment than real-world charging columns.

Electric mobility offers many other fields of application for digital simulation – also at Schaeffler, for instance in the areas of battery and thermal management. “The variety of cell formats, of cathode and anode chemistries in a wide range of installation conditions and customer requirements from micro-mobility to heavy duty call for a highly scalable and adjustable simulation process that seamlessly interlinks design and engineering,” explains Schaeffler’s electric mobility expert Jens Schäfer. “At Schaeffler, we use that to identify solutions at an early development stage and develop products for new traction batteries that satisfy future requirements such as those for ultra-fast charging, longer service life or more stringent requirements for safety in operation.” This partial aspect is another example illustrating the fact that fast-paced technological transformation cannot be achieved without simulations using digital twins.

Pie in the sky

In what direction will the development of the digital twin be heading? Experts predict that, like other systems, due to the accumulation of digital knowledge, the virtual duplicate will increasingly become a learning system that can ultimately act fully autonomously. At that point, humans are going to primarily focus on more complex activities and the further development of such systems.

4 Questions for ...

… Rainer Eidloth, Senior Vice President Engineering IT & Digitalization bei Schaeffler

Do you remember when Schaeffler first started using digital twins for production or for specific product developments?

Since 2016 we’ve been working on creating digital twins in the area of product development of mechanical components. The “Operations” function uses these twins from Research and Development to keep driving digitization on the factory floor and to successively arrive at a holistic data model of the entire lifecycle.

Which twin concept is already helping you save budget and time today?

We’re currently replacing the manual process of incoming goods inspections together with quality assurance by a data-based digital process. Consequently, another element of the twin is created here, namely the link to measurement data systems. The currently complex practice of editing data in Excel files to enable evaluations of purchased parts will be handled digitally in the future. As a result, we’re going to save time and enhance quality.

What forward-looking scenarios do you envision for this development?

Due to the application of digital twins for simulations, costly and lengthy trials with real-world prototypes can be reduced, which cuts costs and is sustainable. Digital twins cannot replace physical products but they help design and operate them in more reliable, durable and sustainable ways. The deployment of digital twins for reporting and controlling purposes will also significantly help achieve our ambitious sustainability goals.

How has the world of work changed for you personally due to these new trends?

Due to shared data models, the collaboration with customers becomes closer and joint simultaneous work in development turns into a reality. Platforms enabling that – such as Catena-X as an open data ecosystem for the automotive industry – are currently in development.