The enablers

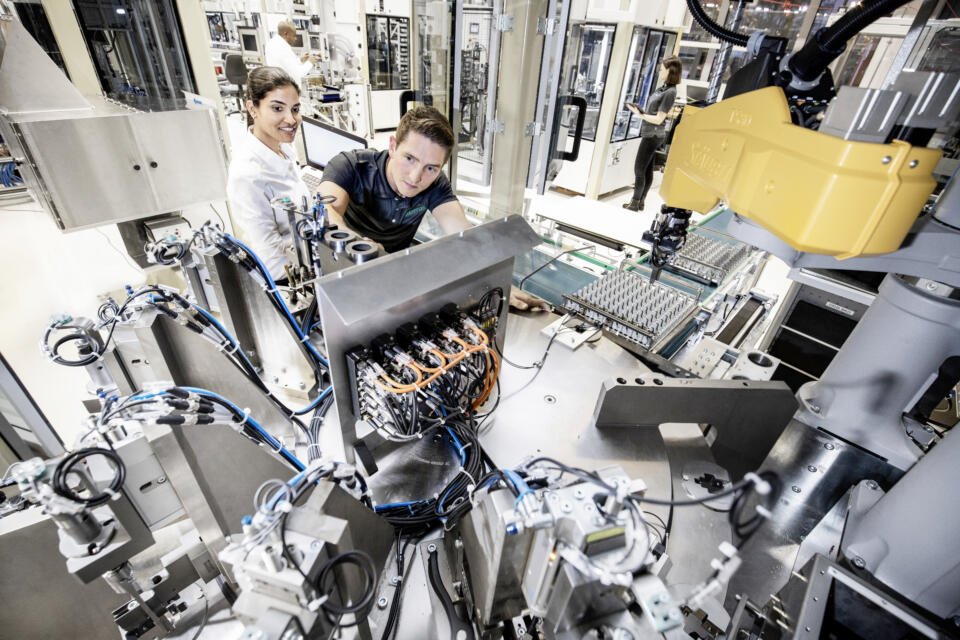

The 1,800 mechanical engineers at Schaeffler tackle any technical challenge posed by a product or a completely new production process. The portfolio of these resourceful specialists encompasses metal-cutting machines, assembly automation, inspection technology and IT solutions in the production environment. It’s focused on specialized solutions for manufacturing automotive and industrial products that are not available on the market. More recent highlights include the development of prototypes, complex assembly or inspection lines for hybrid modules, the thermal management module and the new E-axle transmission systems produced in Herzogenaurach for Audi and Porsche models.

“We define ourselves as ‘partners for production excellence.’ The relationship with our production sites in a spirit of partnership has a decades-long history of guaranteeing that our plants operate like Swiss clockwork and our products meet the highest quality standards,” says Bernd Wollenick, who is responsible for the worldwide special-purpose machinery network with 16 locations. About 50 percent of the group-wide demand for production equipment is met by the in-house special-purpose machinery engineering unit.

The business unit has a total assembly area of some 30,000 square meters (7.4 acres) equating to the size of four soccer fields. This is where the equipment and machines Schaeffler uses to manufacture far more than 10,000 different products are created.

3,000 turning and milling centers

and more than 3,500 grinding machines are used at Schaeffler’s plants worldwide.

On board from day 1

Wollenick’s teams contribute their expertise at a very early stage: whether the project involves small-volume production or a high-output line, manual work or fully automated processes. “A product to be manufactured in our environment may change 1,000 times in its creation stage and many of these modifications are machine-relevant. That’s why we sit at the table as early as in the product design stage of our customers,” Wollenick explains. “Production costs are incurred in product design, and with our agile methods and simultaneous engineering, we ensure manufacturing and economic feasibility.” The electromechanical roll stabilizer that enhances driving safety and went into production in 2015 is a case in point. Its product weight of 14 kilograms (31 lb) and length of up to 1.4 meters (4.6 feet) alone make the handling processes more difficult within the planned assembly and inspection lines. For this and other reasons, it was essential to plan the required production equipment to ensure that the individual components could subsequently be assembled.

Uniqueness protects against copycats

Brothers Dr. Georg und Dr. Wilhelm Schaeffler deliberately relied on machines of their own on the factory floor early on. In 1960, the first “tooling and equipment engineering department” began its work in Herzogenaurach.

The decision was supported by the conviction that technically sophisticated products could be produced in-house in the most economical manner by developing and exclusively using the company’s own machines instead of purchasing them from external suppliers. In this way, Schaeffler secures important manufacturing and assembly know-how and shortens time-to-market for complex products. This in turn enhances the company’s independence and leads to competitive advantages. Only few machines actually end up in third-party hands as part of the systems business, such as the assembly equipment for Schaeffler’s propshafts that have been a top seller for 50 years: a principle that has proven to be viable to this day.

“When you look at the many hidden champions in this country you’ll see that most of them have their own mechanical engineering departments for the factory floor,” says Wollenick. “Besides creating special quality products, this makes life more difficult for the world’s copycats.” When he took the helm in 2007, such departments existed at several major Schaeffler locations, but all of them were working in isolation. Wollenick reorganized them and merged the individual departments into a global unit with standardized processes and work principles.

He went on to drive the internationalization of the special-purpose machinery unit, primarily in China and Slovakia. Today, the largest facilities of the global network are located there. The move to Erlangen in 2017 with a concentration of diverse skill sets in a new headquarters with space for 650 employees marked another milestone.

Campus life promotes collaboration

As soon as you enter the building you can tell that this business unit lives collaboration and innovation on all levels. Colleagues – whether engineers or skilled workers – from diverse functions and across department boundaries work together in shared spaces. Everything has been designed according to the New Work concept – from shielded multi-spaces to writable walls. None of the employees has a permanently assigned workspace. “We look for a place that fits the requirement and constellation of the team and project work that’s important to us,” says Wollenick. This was a novelty at Schaeffler and the concept has produced a noticeable increase in efficiency and innovation.

We guarantee that our plants operate like Swiss clockwork

Bernd Wollenick,

Head of Special-Purpose Machinery Engineering at Schaeffler

“From here we control a global network with 16 locations and are able to realize large-scale international projects across locations: from the initial machine or line concept to stable zero-defects production,” Wollenick explains.

Measured by its numbers, the business unit is even one of the world’s major special-purpose machinery producers today. Nearly 4,500 projects and orders were implemented in 2018 with annual sales amounting to 363 million euros – in very challenging times. “Lean” is in. Lead times and innovation cycles are getting shorter. Due to the major changes in the automotive sector and the product offensives with hybrid electric and battery electric vehicles, the business unit has to establish machines and lines for volume production at an increasingly fast pace. However, today’s environment calls for more than just setting up the systems. 360-degree support is in demand: in addition to planning, consulting, project design and development, the service portfolio of the unit encompasses quality assurance, machine maintenance and customer training for long-term operation.

Special-purpose engineering 4.0

Like Schaeffler’s product portfolio itself, the production processes are subject to continuous change. The progress of digitalization has a major share in this. Consequently, the special-purpose machine engineers also focus on equipping and connecting existing machines and new generations with smart software solutions, sensors and interfaces. Tracing systems for end-to-end quality assurance of products have been developed as well. Traceability detects defects in time and thus helps avoid costly recalls. Vision systems for quality assurance of manufacturing processes by means of artificial intelligence are moving into focus, too. These systems use high-resolution industrial cameras that recognize the geometry, color or position characteristics of products as well as counterfeits.

In addition, the business unit designs, develops and installs technologies in the area of human-robot collaboration (MRC). The product portfolio extends from automated high-speed pick & place applications to highly complex assembly processes using collaborative robots. These cobots are the fastest growing segment in the robotics market. In addition to the classic industrial robot that, permanently installed in a cage and shielded from its human colleagues, keeps performing the same staccato-like movements over and over, this is a smart way to achieve automation in collaboration with humans.

Machine parts from a 3D printer

Schaeffler has been using 3D printing technology for many years. Engineering designers have access to a wealth of tools, from the concept design to the printed component. The technology increasingly enables the production of spare parts and complex plastic or metal machine components. The special-purpose machinery unit also uses these benefits for so-called additive manufacturing. Today, one in two machines already contains at least two components from a 3D printer: a trend that will continue to grow.

18 months

is the average time that elapses between the decision and launch of a new Schaeffler plant. Not only the machines but also the entire material flow and space utilization concepts are based on identical worldwide standards.

New markets, new horizons

Along with the tasks, professional fields and job profiles change. Bernd Wollenick’s team of mechatronics specialists, mechanical and electrical engineers and technicians, technical writers and sales experts has been joined by 100 software developers. This is another growing trend although there’s yet another trend that’s far more important: The special-purpose machinery unit is increasingly opening itself up to other sectors. “By opening ourselves to other markets we want to actively benchmark ourselves and aggressively place competitive technologies in the marketplace,” Wollenick explains. The business unit is currently involved in numerous discussions with potential new customers.

They include international manufacturers in diverse sectors who are interested in metal-cutting machines, assembly and inspection lines or handling and feeding technologies from Schaeffler. “All sectors are conceivable. This will not only broaden our horizons but in turn also enhance our traditional business.” But even the move from a specialized to a mass market is no longer taboo for Schaeffler. The demand for lean, capital expenditure optimized machines at a lower price is high, especially in emerging markets.”

“However, this is a real balancing act,” Wollenick cautions. “Our special-purpose machinery engineering is the operational backbone of the Schaeffler plants and quality ‘Made by Schaeffler’ is our spinal cord. This will always be our top priority – in keeping with the proven tradition established by our founders.”