Steely farmhands

At first glance, the game-changing machine looks like a huge, voracious insect: a tracked vehicle at the front of which four slightly angled screw conveyors form a metallic mouth. Towering above it is an awe-inspiring boom. Sitting in the middle is the operator’s cabin, behind which is a tall conveyor arm. The unusual sight turns out to be a sugar cane cutting machine. It’s parked in the machine hall of Antônio Cury, owner of the Estiva agricultural operation. The 62-year-old comments about the harvester: “It marked the beginning of a new age in Brazil.”

3,000 hectares, four million-euro sales

Fazenda Estiva is located near the small town of Ituverava in the Brazilian state of São Paulo. Ituverava is the center of a region dominated by agriculture. The town is surrounded by rolling hills with fertile red soil. The climate is sub-tropically warm. “These are ideal conditions for large-scale cultivation of various crops,” says Antônio Cury. It’s not for nothing that the region is called “Brazil’s California.”

Recent decades have seen an amazing transformation here. While up until the late 1980s cotton was still being planted around Ituverava, the farmers subsequently began to specialize in corn and soy beans. Around the turn of the millennium, a sugar cane boom began, continuing to this day, driven by the demand for bio fuel. Today, the fields with the bright-green sugar cane stalks extend as far as the eye can see. The risks entailed by such monocultures are known around the globe: soil degradation and a fast proliferation of pests.

Brazil’s agricultural power

Brazil has become one of the top three in the global ranking of agricultural nations. The country currently has a five-percent share in the global trade in agricultural raw materials. Agricultural Minister Blairo Maggi, who is one of the world’s major soy bean farmers himself, is aiming for an increase to ten percent. Brazil is the leading exporter of sugar, orange juice and coffee, and in the top rankings in terms of soy bean, beef, chicken meat and pulp exports as well. For Brazil’s national budget, agricultural exports are indispensable. More than 40 percent of the country’s exports are of an agrarian nature. This transformation is all the more remarkable as Brazil as late as in the 1970s was still importing food. Productivity per hectare (2.47 acres) back then was 1.4 metric tons (1.54 short tons). Today, it’s 4.5 metric tons (4.96 short tons). This increase is attributable to the use of agricultural chemicals and growing mechanization. Within a few decades, Brazil’s traditional, hardly mechanized agriculture was transformed into an ultra-modern industry. Factors with a favorable effect on mechanization are the climate, improved access to capital for the farmers and fertile land enabling the utilization of machines. Some 20 percent of Brazil’s area is used for breeding cattle and eight percent for growing crops. The OECD-FAO Agricultural Outlook predicts that by 2024 Brazil will be the world’s largest agricultural exporter.

Antônio Cury is one of the major farmers in Ituverava. His “fazenda” covers 3,000 hectares (7,413 acres) of land and he employs 40 people. Cury harvests 230,000 metric tons (253,000 short tons) of sugar cane per year which he sells to three factories that convert them into sugar and ethanol, and produce electricity from incinerating the bagasse. His annual sales volume, expressed in euros, varies between 3.2 and four million.

Large-scale operations such as Cury’s have helped turn Brazil into the world’s major sugar cane producer. The country today harvests as much as its six closest competitors on the world market combined. This is a trend that characterizes Brazilian agriculture in general. Be it coffee, soy beans, corn, oranges or beef: Brazil ranks among the world’s major producers. This wouldn’t be possible without the use of specialized machines. In the sugar cane sector, the country has practically seen a technological revolution.

95-percent mechanization

“I was a pioneer,” says Antônio Cury. “I was the first in Ituverava to grow sugar cane. Over the years, I increased my yield by 20 percent.” This success, he says, is owed to mechanization. Modern machines deliver speed and precision.

Cury’s machinery line-up consists of 40 vehicles including a new twelve-ton tractor (13.2 short tons) with GPS and 225 horsepower which he uses to pull heavy plows. His most recent acquisition though is a spraying vehicle equipped with an onboard computer that applies pesticides in previously programmed quantities with sectional precision in a field. Ground clearance of 1.35 meters (4.4 feet), spray arms with a span of 24 meters (78.7 feet), an insulated driver cabin preventing ingress of pesticides and the high speed of 50 km/h (31 mph) are other characteristics of the machine that costs about 200,000 dollars. “This vehicle performs the work of ten conventional tractors,” Cury enthuses – and now it’s clear why operations like his are referred to as Precision Farming.

Mechanization is a game changer

Antônio Cury,

Agricultural entrepreneur

The stars, though, says Cury, are the sugar cane cutting machines: “They’ve been game changers.” Only a few years earlier, sugar cane was being cut in Brazil by seasonal workers using machetes. Before cutting the plants, the fields were set on fire to rid the stalks of the leaves. These days are over. In 2014, 95-percent mechanization of the sugar cane harvest was achieved in Brazil.

What this looks like can be watched a few kilometers away from Cury’s fazenda. There one of the harvesting machines literally cuts its way through a field at a speed of 20 km/h (12.4 mph). With a forward arm it cuts the leaves off the stalks which it then severs slightly above the ground and then picks up. Inside the machine, the stalks are cut into pieces before being ejected into a truck traveling alongside the machine. Cury himself owns only one of these harvesting machines. It’s common practice, he says, to rent them from the sugar cane factories, which is cheaper and easier.

However, Cury points out when we leave, that the best machines are useless if it doesn’t rain. Unfortunately, he continues to explain, dry spells have been increasing in recent years. Experts assume that the absence of precipitation has something to do with the cutting of the rainforest in the Amazon region 2,000 kilometers (1,250 miles) further north, as less forest leads to less cloud formation. The Amazon rainforest is cut for huge fields of soy beans and cattle pastures. It’s the downside of industrialized farming operations like those of Antônio Cury.

Contrasts: 344 hectares, 170,000 euros in sale

600 kilometers (373 miles) south-east of Ituverava farmers are struggling with dry spells as well. At Fazenda St. Rita, a foreman is just in the process of hitching a plow to one of the farm’s two tractors. A small field is to be prepared for sowing corn – although there hasn’t been enough rain yet, says the fazenda’s manager, Amauri Almeida. Fazenda St. Rita is located in a narrow high valley in the mountainous region of the state of Rio de Janeiro. On some 90 hectares (222 acres) Almeida, assisted by ten employees, grows corn, coffee and vegetables: beans, tomatoes, zucchini and eggplant. On another 254 hectares (628 acres) they keep about 400 cattle. In addition, the fazenda includes a small chicken farm.

Although Almeida is not the owner of Fazenda St. Rita – who lives four hours away in the metropolis of Rio de Janeiro – he has been its manager for 27 years. Once a week he has the farm’s produce hauled to a central market in the valley on an old truck. In total, the fazenda generates sales of 170,000, expressed in euros.

Like in the old days

Fazenda St. Rita fundamentally differs from Fazenda Estiva in Ituverava, not only in terms of statistics. It represents the other side of the Brazilian agricultural model. While Precision Farming takes place there with computer-controlled machines on huge mono-culturally planted areas, farming here is almost like it used to be in the old days. Almeida’s employees harvest most of the vegetables by hand, even corn is picked manually. “We’re small but proud of producing food for the population,” says Almeida. There’s certainly truth in this. While the production by the large-scale operations is primarily intended for export, 70 percent of the food consumed by Brazilians is produced by small to mid-sized farms such as Almeida’s.

The small farms achieve this exclusively due to their large numbers. 4.4 million of them are registered in Brazil, employing 14 million people. They can hardly afford machines. It’s been four years that Almeida has made his most recent major acquisition: a tractor with 75 horsepower for 29,000 euros (converted from pesos). Up until that time, the farm was using a single tractor built in 1982. The new machine, explains Almeida, was a compromise between performance and weight because if the tractor were too heavy it would compact the soil. The machine is used for all kinds of purposes: for plowing, for sowing, for application of pesticides, but also for pulling trailers with vegetable boxes. “It’s our universal workhorse,” says Almeida.

If I run out of co-workers, I’ll need suitable machines

Amauri Almeida,

Small farmer

Besides the dry spells, the 54-year-old describes the uneven terrain as the greatest challenge. That’s why he’d like to have an additional small tractor allowing him to drive down the steep slopes between the vegetable fields and coffee plantations. But he hasn’t found one yet on the market. “We’re a small farm,” he says, “but we’d like to grow.” In the future, though, exactly that will more than likely only be achievable with suitable machines. For a simple reason: Almeida is running out of workers. The average age of his ten employees is 45 years and their sons and daughters would rather look for jobs in the city than get their hands dirty in the fields.

Almeida cannot understand that. He’s been working at Fazenda St. Rita for 27 years, not having taken a single vacation during this time. “It’s nothing I miss,” he says. “I find fulfillment in my work. And if I run out of co-workers, then I’ll just need suitable machines.”

The plow

The plow is one of the oldest agricultural tools still in use today. Tools similar to a plow were even used by the very first crop farmers to loosen the soil. Through the ages, the positive effects of plowing have been the supply of oxygen to the soil, plowing in weeds and harvest residues and the destruction of the tunnels and nests of field mice and other pests. Apparently as far back as in the Neolithic Age, the first farmers would plow furrows across their fields using very simple tools that consisted of nothing more than sharpened wooden sticks. The oldest discovery of a plow in Europe was made in today’s Switzerland, the tool’s age dating to the middle of the 5th century B.C. Whereas the early farmers would still pull their plows themselves, draft animals were used later. The utilization of tractors only started in the 20th century. Accordingly, plows became larger and heavier.

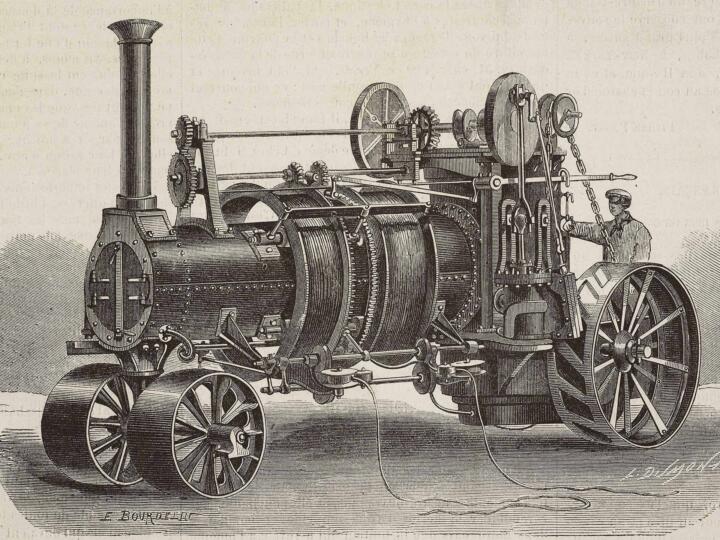

The mechanization of agriculture

The utilization of machines in agriculture was a consequence of industrialization. In Europe and the United States, it began at the end of the 19th century and not only changed the rural economy but social structures as well. Mechanization was one of the triggers of “superfluous” farm help migrating to the cities. The first agricultural machines included tow trucks and tractors. In addition, agricultural tractors changed the livestock of the farmers who needed fewer draft animals, especially horses and oxen. Technological progress was also accelerated by the fact that it was no longer possible to cultivate the huge fields in the Midwestern United States without machines. The United States was also the country in which the first combines were used. One of the first tractor models in Europe was the Lanz Bulldog in the 1920s. A tractor, though, would remain unaffordable for many farmers for a long time. Their utilization only increased after the Second World War.

Smart Farming

How can the world population of nearly 10 billion anticipated by 2050 be fed? The Food and Agriculture Organization (FAO) of the United Nations has calculated that agricultural production would have to increase by 70 percent to achieve this. But will this be possible without destroying our planet’s ecological balance – particularly since most of the land fit for cultivation is already being used? The FAO sees increasing the yield per hectare as the only possibility. This could be achieved by mechanization, the utilization of agricultural chemicals and new plant varieties. A supplementary answer is: Smart Farming. It means that a farmer keeps an eye on various factors – the weather, moisture and mineral content of the soil, weed and pest infestation – and, based on these factors, is able to calculate the ideal application (timing, quantity, location) of fertilizers, water and pesticides using computer models. The GPS-controlled agricultural machines introduced at the beginning of the millennium were a step in this direction. The tracking system, for instance, prevents the machine from “overlooking” a section of the field or working on it twice. The machines by now are interconnected and able to autonomously work in concert.