Scalable and customized

After more than two decades of research and development work and the formation of a dedicated business division three years ago, at the beginning of 2018, Schaeffler’s consistent commitment to electric mobility is reflecting significant success. Numerous delivery contracts awarded by automotive OEMs across all electrification levels prove that Schaeffler has successfully established itself in electric mobility. “We have achieved a lot and continue to be on a very good path,” says Dr. Jochen Schröder, President of the E-Mobility business division. “With our modular product portfolio, we are now in a position to offer a production solution tailored to any customer wish.”

We will be involved in shaping electric and sustainable mobility decisively going forward. For this purpose, we are developing highly innovative solutions – with high vertical integration, modularity and scalability

Dr. Jochen Schröder,

President, E-Mobility business division

Another advantage of Schaeffler as the preferred go-to partner for its customers is that the Group is able to fully cover the entire industrialization of its components and systems in-house. Everything comes from a one-stop shop. Here are some examples from Schaeffler’s extensive modular e-mobility portfolio for environmentally compatible vehicles.

Dedicated hybrid transmission

Dedicated hybrid transmissions (DHT) are highly integrated solutions that have been developed exclusively for use in hybrid electric vehicles. The electric motor is intelligently integrated into a simplified transmission – this saves space and weight, plus it’s cost-efficient in high-volume production. Power output typically ranges between 80 kW and 140 kW. The electric motors of the DHT operate in combination with the IC engine as an additional propulsive force or they produce electric power as a generator, depending on the operating mode of the transmission or powertrain. In 2020, Schaeffler was awarded a record contract for dedicated hybrid transmissions and from 2025 on will deliver an entire drive unit with two electric motors (system output: 120 kW) and transmission-integrated power electronics.

Hybrid modules

The hybridization of conventional IC engines is a major key to efficient, more sustainable and needs-based mobility, at least during a transition period. For 2030, Schaeffler expects a worldwide market share of 40 percent for all newly registered passenger cars with hybrid powertrains. For this vehicle category, Schaeffler offers a modular solution with powerful electric auxiliary drive units, so-called hybrid modules. As electric motors in these applications, highly efficient permanent magnet synchronous and asynchronous motors are used. The modular hybrid system is flexible and can be adapted precisely to various transmissions and motors, for instance as a hybrid module with an integrated torque converter or as a hybrid module with a triple clutch.

E-axle transmissions

Since 2017 e-axle transmissions from Schaeffler have been mass-produced successfully, ensuring optimal gear ratios and power transmission from the electric motor to the wheels for a wide range of applications: In the Audi e-tron, e-axle transmissions from Schaeffler are used in different designs (see illustrations) on both axles for an all-wheel drive system.

In the Porsche Taycan, a highly efficient coaxial e-axle transmission from Schaeffler provides the right gear ratios at the front axle – an award-winning innovation: In 2020, Schaeffler was recognized with the prestigious PACE Award that’s regarded as the benchmark for successful automotive projects worldwide.

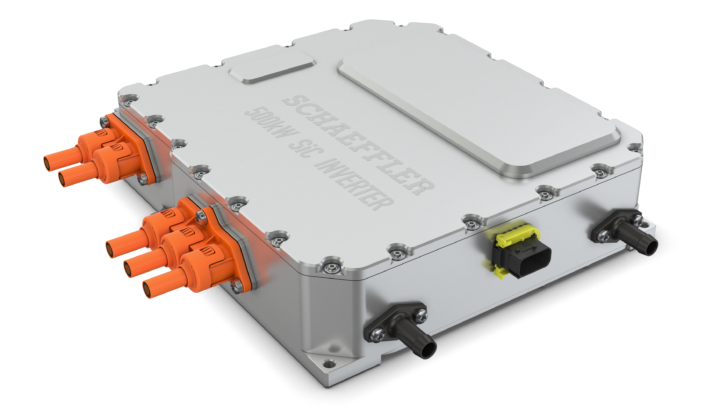

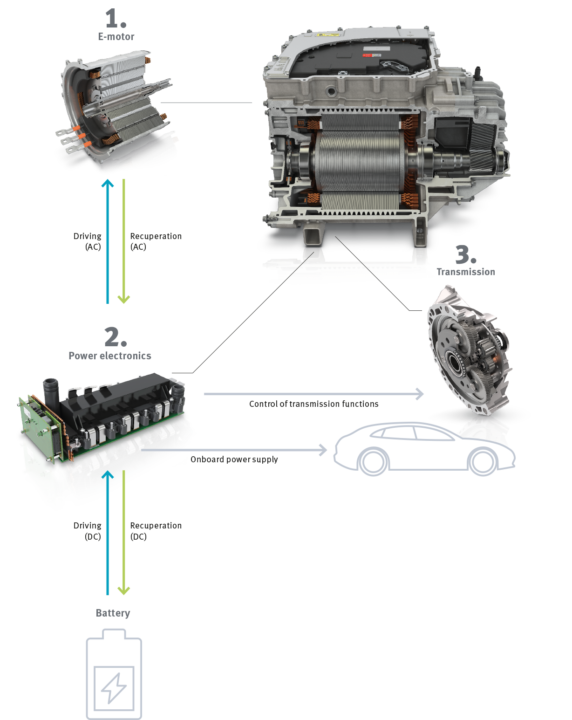

Power electronics

The power electronics unit is the brain of an electric or electrified powertrain. Its main purpose is to control the current flow between the battery and the motor (see also illustration below) using a so-called inverter. It does so in two directions: During propulsion the motor has to be supplied with the right voltage and while braking, the flow direction reverses, the motor recuperates energy and charges the battery with it.

The inverter converts the DC voltage (battery) into AC voltage or vice versa. In addition, the power electronics unit acts as the “reverse gear” of an electric vehicle. For driving in reverse, it reverses the polarity and thus the rotational direction of the electric motor. As a novelty, Schaeffler is now presenting a proprietary 800-volt power electronics unit for application in e-axles of high-powered vehicles. The scalable solution can handle permanent power outputs of up to 330 kW and short-term peaks of up to 500 kW – in spite of small housing dimensions. The utilization of special semiconductors (“wide-bandgap silicon carbide technology”) enables efficiencies of more than 99 percent in defined load ranges. This increases the overall range of electric vehicles considerably. Moreover, due to the 800-volt voltage class, clearly higher charging speeds are achieved than in the previous widely used 400-volt voltage class.

3in1 axle system

In the 3in1 e-axle Schaeffler combines the e-motor, transmission and power electronics in one system. Schaeffler’s propriety software takes care of signal processing and drive control. The powerful 3in1 axle impresses with a compact design, high power density, high system efficiency and excellent acoustic performance. In addition, with its modular structure, the system satisfies diverse use requirements and can be implemented into different vehicle platforms.

Global manufacturing expertise

Schaeffler offers its customers decades of know-how from a one-stop shop and operates a globally interlinked manufacturing network. When establishing production facilities, Schaeffler benefits from the high-level expertise of in-house tooling and special-purpose machinery engineering. Close integration of research and development with prototyping and manufacturing ensures the required agility and efficiency of all processes.

Whether for single components or complete systems, we, as Schaeffler, want to be the preferred technology partner of our customers

Matthias Zink, CEO Automotive Technologies

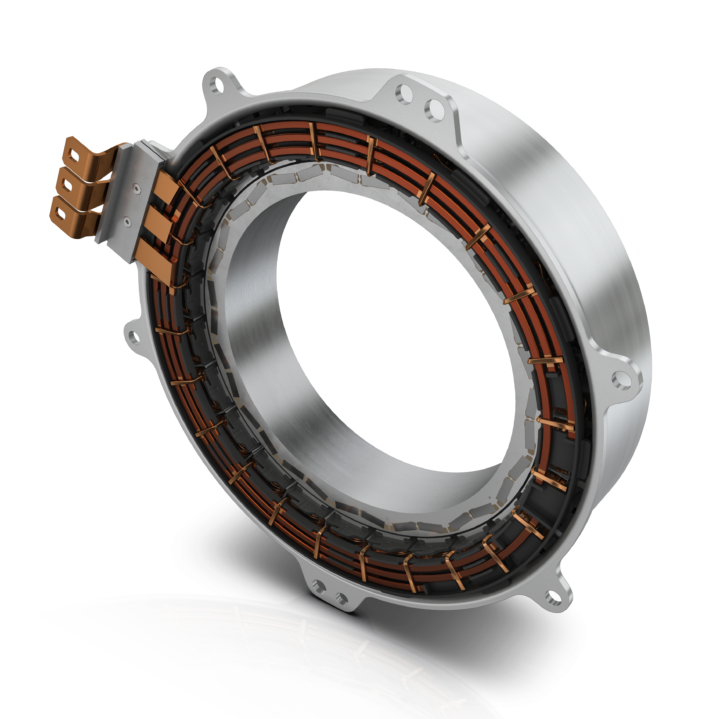

In 2018, Schaeffler decisively strengthened its capabilities in electric motor engineering by acquiring Elmotec Statomat, the leading manufacturer of mass-produced electric motors. Elmotec Statomat has unique expertise in winding technology and been a technology leader in the field of production machines for electric motors for more than 60 years. Especially rod wave winding technology is regarded as a leading technology in terms of power density, efficiency and efficient mass production going forward.