Preventive action

The key question is: what spare parts and services will still be needed in the future? Even though hybrid and battery-electric vehicles – irrespective of their type of powertrain – only become relevant to the independent aftermarket at an age of more than five years, Schaeffler’s Automotive Aftermarket business unit is gearing up now to serve coming needs: it’s the first supplier to offer a repair kit – even before 48-volt hybrids start hitting the garages for routine repairs.

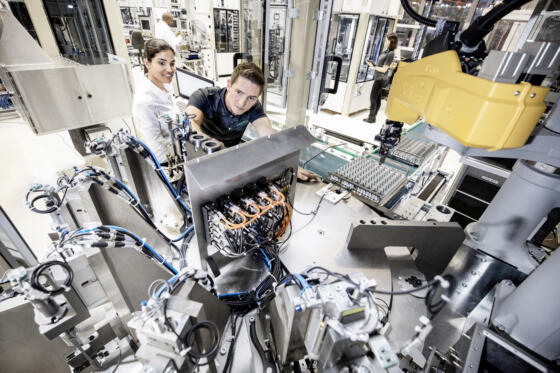

48-V hybrid powertrain systems

deliver 7 % better fuel economy compared to a conventional IC engine.

Source: Schaeffler

On 48-V hybrids, the conventional alternator is replaced by a belt-driven starter-generator – a so-called PO architecture. While switching from the charge phase to the boost phase, the direction of the belt drive’s torque is reversed. In addition, this directional change and the higher output of the generator result in higher loads acting on the V-ribbed belt, bearings and other components. Therefore, the INA FEAD KIT repair solution (FEAD = Front End Auxiliary Drive) for 48-V hybrids developed by Schaeffler additionally includes a decoupling tensioner and a pulley decoupler to absorb these special loads in the auxiliary component drive. This makes it possible for garages to perform fast and professional repairs in the event of damage to the auxiliary component drive.

More electrical output

The 48-volt mild-hybrid technology opens up new opportunities: while the conventional alternator is a simple generator of electricity, the FEAD system morphs into a bi-directional energy supplier.

Conventional alternator

Output approx. 2 kW

Torque approx. 7 Nm

Belt-driven starter generator (BSG)

Output approx. 15 kW

Torque approx. 50 Nm

Schaeffler solutions

Schaeffler Virtual Experience Platform

Virtual trade fair can be visited to find out more about other components from Schaeffler.