On the road toward a biobased economy

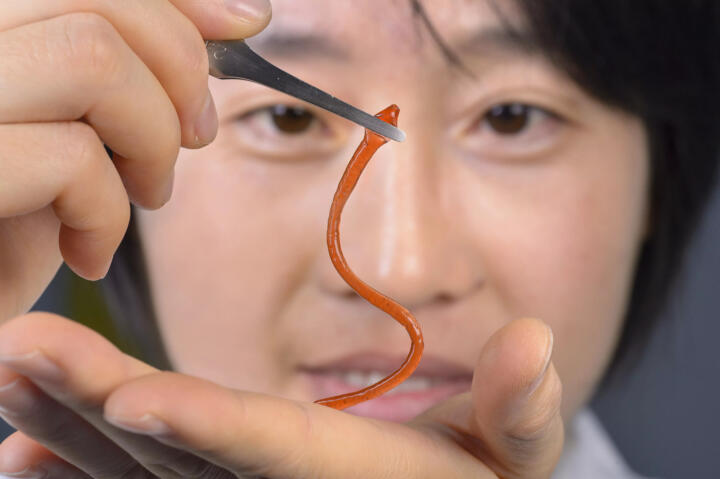

The cell clusters are moving around frantically in a petri dish. They’re so-called Xenobots, artificially created from tissue and stem cells of the frog Xenopus laevis from which their name derives. With their C-like shape they’re reminiscent of the video game character Pac-Man. The tiny creatures are propelled by extremely delicate cilia (tiny hairlike structures) that were implemented in the Xenobots by cell manipulation as well. During their seemingly chaotic ride the microorganisms gather stem cells that look like grains of sand on a sheet of glass. Soon after, cell clusters that increasingly resemble the original organisms start forming in front of their “mouths.” The Xenobots are in the process of duplicating themselves. This already marks their third evolution after previously having learned to move and to repair themselves.

Xenobots were created by a team of biologists at Tufts University in Boston (USA) and computer scientists at the University of Vermont (UVM). A biotechnology collaboration that has just begun. “We want Xenobots to do useful work. Right now, we’re giving them simple tasks, but, ultimately, we’re aiming for a new kind of living tool that could, for example, clean up microplastics in the ocean or contaminants in soil,” says UVM robotics expert Josh Bongard. In the foreseeable future, Xenobots are also supposed to help deliver medications directly to the places in the body where they’re most effective or help detect and treat diseases.

Xenobots are a good example of visionary biotechnology – but by far not the only one. “The biologization of industry can lead to the same progress as digitalization does,” Prof. Dr.-Ing. Tim Hosenfeldt, Senior Vice President, Corporate Research and Innovation & Central Technology at Schaeffler, is sure.

Even da Vinci used biotechnology

Although biotechnology may sound like science fiction, humans have been using it in production processes for a long time. An example that’s thousands of years old is the utilization of yeasts in bread, beer and wine production. Today, experts refer to biointegration or frequently also to “white biotechnology” in the context of incorporating active biological components into technical processes and products.

A second field of biotechnology is bioinspiration or bionics, in other words copying of natural properties for technical products and processes. Leonardo da Vinci (1452–1519) – unsurprisingly – is regarded as the first bionics scientist. After having extensively studied the flight of birds, the universal genius designed flying devices, helicopters and parachutes. A farmer named Michael Kelly wanted to keep his livestock in check and copied a thornbush. In 1868, he registered a patent for his barbed wire – another example of early bionics. The first industrial robot named Unimate that was presented in 1959 bore an obvious resemblance to a human arm and was equally suitable for multifunctional uses. Even today, buckling arm robots are still based on this bionic design principle. In surface technology, the lotus effect is a well-known bionics invention. The complex micro- and nanoscopic architecture of the lotus plant causes liquids and dirt particles to roll off the surface and has been copied thousands of times for products and applications.

Biointelligence is regarded as the third, important and most recent, field of biotechnology, in which technology, biology and information technology merge. Here biological elements can be controlled by data processing systems and incorporated into a technical system. Fingerprint activation, retina scanning and voice commands issued to artificial intelligence systems like Siri and Alexa are popular examples. And the previously described Xenobots are a biointelligent application as well.

Key technologies to combat climate change and curb resource consumption

“Nature is the highest form of self-organization that has been optimized throughout millions of years of evolution. Not to exploit this potential to master the pending challenges posed by climate change, population growth and resource consumption would be grossly negligent,” warns Schaeffler’s head of research, Tim Hosenfeldt. Everywhere in the world researchers are engaged in doing exactly that: integrating nature more efficiently in circular production processes and value chains – from material extraction to material decomposition.

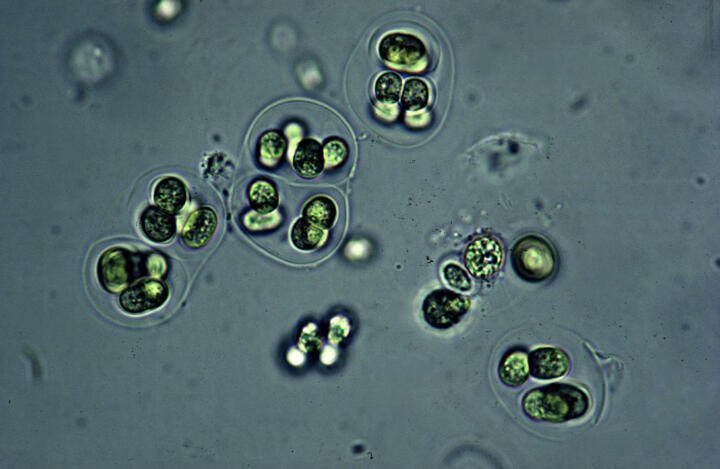

On a global scale, microorganisms and their enzymes, i. e., the complex protein molecules that accelerate biochemical reactions in all life forms, are the focus of attention. Progress achieved in genetic engineering opens up increasingly new opportunities for researchers to establish microbiological process chains, with the enzyme-based metabolism of microorganisms playing a key role in this context. And in the event that it doesn’t fit (which is seldom the case) it will be arranged to fit: through systematic DNA modifications (“genome editing”) the metabolisms of microorganisms are influenced or redesigned (“metabolic engineering”).

The world’s laboratories are developing microorganisms such as bacteria, fungi and algae that decompose plastics in soil and bodies of water or that can be incorporated into other recycling processes – up to and including those of radioactive or toxic substances. Equally important are “producing” organisms that help produce food, pharmaceuticals, chemicals, materials, and biofuels and biogases (see also examples in image gallery).

Such microbiological processes have another advantage: whereas conventional chemical processes require a lot of energy and, in some cases, toxic solvents, products can be produced under milder and more energy-efficient conditions using microorganisms because microbes grow in more eco-friendly aqueous solutions.

The interaction between software, hardware and bioware enables sustainable industrial value creation

Prof. Dr.-Ing. Tim Hosenfeldt, Senior Vice President, Corporate Reseach and Innovation & Central Technology at Schaeffler

Transformation toward a biobased economy

The pressures on industry to act on the need to establish new processes using microorganisms is growing. Schaeffler’s expert Hosenfeldt shares this sentiment: “Society and governments are calling for action regarding sustainability. The appropriate response to this is a biobased economy using renewable instead of fossil raw materials along the value chains of products, processes and services. Biointegration into processes and products is prospering thanks to progress in genetic engineering and is largely accepted. Many players work hand in hand and are market-driven. This has an accelerating effect as well.”

Universities have long begun to respond to this trend too by offering courses of study such as bionic engineering, biobased economics and industrial biotechnology. If such a biobased economy intends to provide a basis for sustainable industrial value creation it also has to master the challenge of expanding the required production of biomass for energy-related and industrial purposes in ways that neither limit the production of food and animal feed nor destroy natural environments. In this context, biotechnology can make crucial contributions as well: by helping to use non-edible plants and plant components and by optimizing cultivable land of inferior quality. Biotechnical innovations are required to meet yet another challenge: large quantities of highly efficient enzymes and microorganisms have to be available at low costs to enable industrial-scale and economically feasible processing of renewable resources into a wide range of preliminary and intermediate products in so-called biorefineries.

In such a biobased economy even the greenhouse gas carbon dioxide can be used as a raw material in a sustainable circular economy. The CO2EXIDE initiative is currently developing an electrochemical process using CO2 removed from the atmosphere to produce ethylene oxide, which is a pre-product of polyester and polyamide production. If renewable energies were used, the resulting plastic materials would have a negative carbon footprint. Schaeffler supports the EU-funded project with its expertise in nano-structured coatings for the development of catalytic converters.

However, the carbon footprint is just one of the components in a sustainable circular economy. At least equally important is the question of what happens with products at the end of their useful life. Biobased plastics, for instance, are equally unsuitable for composting as their petroleum-based counterparts. Consequently, a need for biotechnological action also still exists in the context of such end-of-life considerations.

Copying nature

A bionics research project of the UnitCat Excellence Cluster in Berlin shows that the boundaries between the areas in biotechnology are permeable. The scientists were seeking to copy the protein glue of blue mussels, which is one of the strongest natural adhesives. They succeeded in doing so by using a biointegrative process. “To create these mussel proteins, we use intestinal bacteria, which we reprogrammed,” explains Prof. Nediljko Budisa, a member of the project team. “They are like our chemical factory through which we produce the super glue.” The protein adhesive could be used, for example, to fix broken bones or teeth in place – an option that many medical professionals have been waiting for.

Nature offers a cornucopia of ingenious functionalities that are worth copying. Be it fish gills as microplastics filters, floating ferns for friction-reduced surfaces, bamboo as a highly resilient lightweight-design champion or the good old hook-and-loop fastener that adopted its principle from burs (see also further examples in image gallery).

“Looking at nature pays off with regard to many of the tasks and problems we’re confronted with today. In many cases, nature has already developed something that has prevailed in evolution and that we can adapt,” says Prof. Dr.-Ing. Tim Hosenfeldt. “It’s very exciting to see how nature optimally adapts to conditions and requirements of its surroundings. In doing so, it uses the available energy in very resource-efficient ways.”

Concerning resource efficiency, Hosenfeldt provides an example from Schaeffler’s practical experience: “Through bionic optimization of the housing design we managed to reduce the mass of a wheel bearing by 30 percent while retaining an identical load-bearing capacity.” The principle of systematic omission adopted from nature not only saves resources in manufacturing but also while the product is in use. The bionic component was designed using artificial intelligence. Consequently, the design incorporated technology, biology and information technology – which takes us to the subject of biointelligence.

The dream of self-healing materials

The interaction of software, hardware and bioware opens the gate to many new fields of application, ranging from DNA-based data storage to bioprinting of tissue and biosensors to self-healing machines. Many of these applications are still in an experimental stage, such as DNA-based data storage where the information is not stored in rows of ones and zeros but in the form of DNA data strands that are formed from the basic biological building blocks guanine (G), thymine (T), cytosine (C) and adenine (A). Because these DNA storage strands are highly vulnerable, they require a protective encapsulation. Robert Grass and Wendelin Stark, professors of chemical engineering at ETH Zurich, have developed such an encapsulation from glass particles, for which they were recognized with the 2021 European Inventor Award. Grass estimates that about one exabyte of data (equating to one million terabytes) is stored in one gram (0.03 ounces) of glass-encapsulated DNA. If this biointelligent storage option were usable in mass-compatible ways in the future, energy-guzzling server farms would be history.

And how realistic are self-repairing machines? Programmable “living materials” similar to the previously presented Xenobots might be a key in this context (as well as for many medical applications). “Unlike materials that we synthesize in the laboratory, living materials would have the capacity for self-healing, for adaptation to the environment and even for enhancing their performance during their utilization,” explains Professor Aránzazu del Campo, Scientific Director at the Leibnitz Institute for New Materials INM.

As in many areas of biotechnology, there’s still a long way to go. But to proceed on this pathway is inevitable in view of the challenges to be mastered due to climate change and population growth. Therefore, making use of nature to protect nature is simply logical. Or, as Charles Darvin once put it, “Anything that is against nature will not last in the long run.”