Not all approaches are successful

In the 1860s, Nikolaus Otto, a young salesman who was fascinated by technology, started to work on optimizing the gas engine invented by the Frenchman Étienne Lenoir. His experiments resulted in the so-called free piston atmospheric engine that, due to a modified gas/air mixture and use of ambient pressure consumed two thirds less fuel than Lenoir’s original version. Otto’s first engine weighed 700 kilograms (1,543 pounds) and delivered 0.5 horsepower. It was not suitable for mobility purposes but was useful as a drive system for production machines. Otto continued his research work, developed electric ignition among other things, and in 1876, together with Wilhelm Maybach and Gottlieb Daimler, developed a four-stroke gas engine with compressed fuel charge to production level. Marketed under the name of “Otto’s new engine,” it provided the basis for today’s internal combustion (IC) engines. Gottlieb Daimler soon recognized the potential of the new engine as a means of propulsion on land and water and continued optimizing it together with Maybach. Carl Benz combined the internal combustion engine with a coach-like three-wheeler as the first automobile to hit the road. The IC engine powered by fossil fuels such as gasoline, diesel, or gas is still the dominant powertrain concept for passenger cars and trucks. In the space of roughly one and a half centuries, mobility has been seeing a variety of excursions from the standard but most of those historic development paths ended in dead-end streets time and again. However, there were some promising exceptions presented below.

Steam power

It was regarded as a technical revolution: In the 18th century, the steam engine enabled the mechanization of industry, replacing the horse. Thanks to the combustion of fossil energy sources such as coke, brown coal, wood or oil it was possible to generate steam and to move pistons. The stroke of the pistons could be converted into a rotary motion by means of a crank. In addition to its use in stationary operation, the technology was soon sought after in mobile uses such as steam-powered ships, locomotives, cars and commercial vehicles. However, the gasoline-powered IC engine with its clearly better efficiency and more compact design only started replacing the steam engine on the road at the end of the 19th century.

Electric motor

In 1835, Thomas Davenport, a blacksmith from Vermont, operated a small model car on a section of track with a diameter of about one meter (four feet). Even though that failed to inspire widespread interest it was a global sensation because Davenport built the first electric car. In 1837, he secured the first patent for an electric motor worldwide. Ever since then, engineers have been thinking about ways in which electric power can move people from A to B – long before the first internal combustion engine. When Austrian electrical engineer Nikola Tesla invented the AC motor in 1882 electric power finally seemed to have become the mobility solution in terms of the powertrain. The German “Flocken Elektrowagen” from 1888 is regarded as the world’s first electric car. The first motorized trip at triple-digit speed was achieved with an electric vehicle too: in 1899, the Belgian Camille Jenatzy in his “La Jamais Contente” reached a speed of 105.88 km/h (65.79 mph). Around 1900, 40 percent of the automobiles in the United States were steam-powered cars, 38 percent were electric cars and 22 percent were gasoline-powered cars that had to be refueled from bottles bought in pharmacies. Shortly before the beginning of the First World War the tides turned in favor of the internal combustion engine. The first fuel pumps considerably simplified refueling, and assembly line production introduced by Henry Ford made cars with IC engines clearly more affordable than their battery-powered competitors. The rest is automotive history, but now it’s becoming increasingly clear that the tides are turning again in favor of the electric vehicle. Experts at Schaeffler expect that in 2035 “only” about 15 percent of all newly registered cars will be powered exclusively by internal combustion engines worldwide. Sometimes it takes a little longer for a technology to catch on …

New energy sources

Alternatives besides petroleum also acquired some significance depending on overall economic and environmental conditions. Palm oil and rapeseed oil as plant-based substances are suitable for diesel engines. Ethanol, an alcohol, can be used in gasoline engines. Following the oil crisis in the 1970s, Brazil unhitched itself from the petroleum market with this alternative. Gases like liquid petroleum gas (LPG), compressed natural gas (CNG) or biomethane are suitable for use in internal combustion engines as well. While the first generation of biofuels used the fruit of plants (oil, sugar and starch) in competition with food production, the second generation is based on parts of plants that are not used as food. The group of synthetic fuels is gaining importance. They replace mineral oil by other energy sources, in many cases help avoid CO2, depending on the substances and technologies involved and thus provide alternatives to electric drive systems. X-to-Liquid (XtL), Gas-to-Liquid (GtL), Biomass-to-Liquid (BtL) or Coal-to-Liquid (CtL) have been established for some time. In the case of Power-to-X (PtX), process engineers split hydrogen and oxygen by means of electricity. Subsequently, by means of Power-to-Gas (PtG), they produce methane, or by means of Power-to-Liquid (PtG), liquid fuel from hydrogen and other substances, especially carbon dioxide. Hydrogen can also be used directly, for instance in fuel cell powertrains or in internal combustion engines. Besides price, efficiency and emissions of individual substances make the difference between success and failure of such solutions. In addition, political considerations affect legislative frameworks, which may lead to highly different national assessments that are often subject to change over time.

Solid fuels

In more than one and a half centuries of automotive history, the saying “necessity is the mother of invention” proved to be true more than once. In times of war when fuel was in scarce supply, shortages made the use of energetic alternatives imperative. The wood gas generator that was primarily used in Germany during the Second World War converts timber into charcoal at high temperatures. The charcoal reacts with steam to create generator gas, the actual fuel for the conventional internal combustion engine. However, the range of such vehicles amounted to merely 50 to 150 kilometers (31 to 93 miles), plus the combustion residues had to be removed every 20 to 30 kilometers (12 to 18 miles). In addition, the unfavorable energy density – two times lower than that of gasoline – meant that in case of doubt the driver had to haul along larger amounts of timber on a trailer. The idea of using coal dust as a fuel produced only moderate results due to inadequate power output.

Stirling engine

Unlike an internal combustion engine, a Stirling engine requires an external heat source because it does not produce thermal energy on its own. The external source heats the gaseous working fluid in the Stirling engine which in turn through expansion displaces a piston before cooling down in a second cylinder. The gas oscillates between both spaces while changing pressure and temperature. Using con rods and a crank, the two pistons cause an axle to rotate. In this way, the engine converts thermal into mechanical energy, which can be used for generating electricity, for example. However, the engine requires a long time to heat up. Due to its sluggish response, it’s hard to control and therefore unsuitable for use on the road. Its efficiency increases with the size of the heat transfer unit so that the size and weight of the engine are unfavorably high. That makes the powerplant suitable for stationary uses but not for automobiles. Principally, the engine that was patented at the beginning of the 19th century can be combined with an IC engine or with solar thermal power. Its use makes sense also in combined heat and power plants and NASA is planning to use it in space probes as well.

Rocket engine

Automobiles with rocket engines have in fact existed and continue to do so – albeit – and fortunately – not for use on the road. 1928 saw Fritz von Opel barreling down Berlin’s Avus racetrack in the Opel RAK 2, and when it comes to setting speed records on land, rocket engines have been dominating events since the middle of the last century, for instance on the Great Salt Lake in Utah. In daily transportation settings, though, the rocket is unfit for use: exhaust emissions are far too hot and the principle of the reaction engine is incompatible with the pace and rhythm of road traffic. Even so, it’s a historic fact that rocket engines have played a specific role in enhancing road traffic safety. Mercedes-Benz, for instance, used hot-water rockets from 1962 to 1973 to accelerate trial cars in crash tests. Tow ropes have long since then assumed this role in terms of acceleration.

Flywheel or compressed air as hybrid storage systems

Whereas battery-electric storage systems have become standard in today’s hybrid-electric powertrains, other storage solutions have not been successful. As far back as in the 1950s, gyro buses were being operated in Switzerland and in Belgium. Using extensible roof-mounted booms for overhead charging at bus stops, their flywheels weighing some 1.5 metric tons (1.6 short tons) could be accelerated again within a matter of minutes. They enable gyro buses to achieve a range of several kilometers before recharging at the next stop. For use in motor racing, high-tech flybrid systems were created as complements to internal combustion engines. They were deployed in Formula One starting in 2008 and at Le Mans starting in 2011, for instance by Audi, but never gained acceptance on the road. Neither did the compressed air hybrid make it into mass production. Peugeot had presented its HYbrid air system with a compressed air accumulator in 2013. The brand claimed to have reduced consumption of the 2008 model range to 2.9 liters (0.76 gallons) in that way. The compressed air was connected to the powertrain via a hydraulic system and a transmission. Lightweight design concepts such as Volvo Air Motion, Honda Air or AirPod from Motor Development International using strictly pneumatic power never made it beyond the concept stage.

Solar propulsion

Using solar energy as a source of propulsion sounds enticing, but the efficiency of solar cells of around 20 percent is so low that in spite of announced models such as Sono Sion, Lightyear One or Aptera Sol no solar automobile exists in retail yet. Solar roofs available in production vehicles – such as in the Hyundai Ioniq 5 – merely serve to supplement the charging current supplied by the power outlet. However, the solar roof for the VW ID offered by Schaeffler’s partner ABT e-Line with a peak capacity of 600 watts can supply energy for up to 3,000 kilometers (1,864 miles), according to the manufacturer. For extremely lightweight prototypes on the other hand, the power supplied by the onboard solar cells does suffice for locomotion: since 1987, for example, the best teams have been competing in the World Solar Challenge in Australia (www.worldsolarchallenge.org). The solar idea has been finding friends also on water and in the air: in 2016, the Swiss Bertrand Piccard in the “Solar Impulse 2” aircraft using 17,000 installed solar cells managed to circumnavigate the Earth. Thanks to large roof areas, solar boats, some of them accommodating a triple digit number of passengers, have found their way onto the world’s bodies of water. They travel in India, Spain, on the Côte d'Azur and on the Baltic Sea.

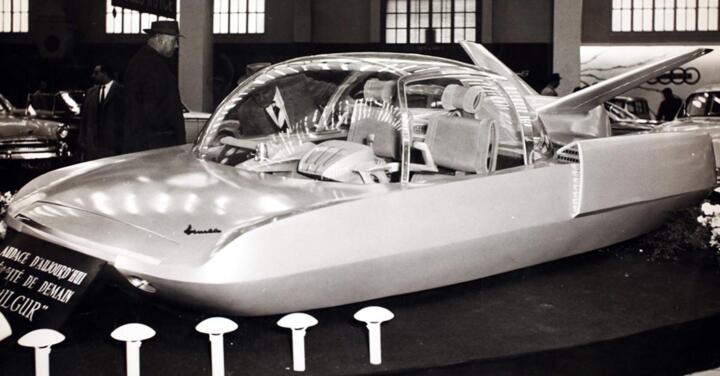

Nuclear drive

Unbroken faith in progress was conductive to Ford unveiling to the world a concept called Nucleon in 1958. According to the wishful thinking of its developers, a nuclear reactor was supposed to have propelled the car featuring strange proportions. How such a system could have been miniaturized and cost-efficiently operated remains a secret – not to even mention the safety aspects in road traffic. The Simca Fulgur and the Studebaker-Packard Astral merely represent visions of nuclear powertrains during that era as well. However, ships propelled by nuclear systems do prove that nuclear power can be used not only in stationary powerplant settings: submarines, aircraft carriers as well as nuclear icebreakers or the former German freighter Otto Hahn rely on nuclear fission.

Read more

Gas turbine

Whereas turbine engines rapidly displaced piston engines in aircraft after the Second World War the transfer of that technology to the road failed. The Rover Jet 1 concept and the Fiat Turbina at the beginning of the second half of the 20th century remained one-of-a-kind. At the beginning of the nineteen-sixties, the Chrysler brand handed over a few dozen trial cars of the Chrysler Turbine to selected customers for testing but terminated the program after completion of that long-term test. High fuel consumption and delayed acceleration are just some of the turbine’s disadvantages. Jaguar integrated this technology in a hybrid powertrain of the C-X75 sports car in 2010: two micro gas turbines served as range extenders for charging the traction battery supplying the energy to four wheel hub motors. That was another trial to have gotten stuck in the concept stage.

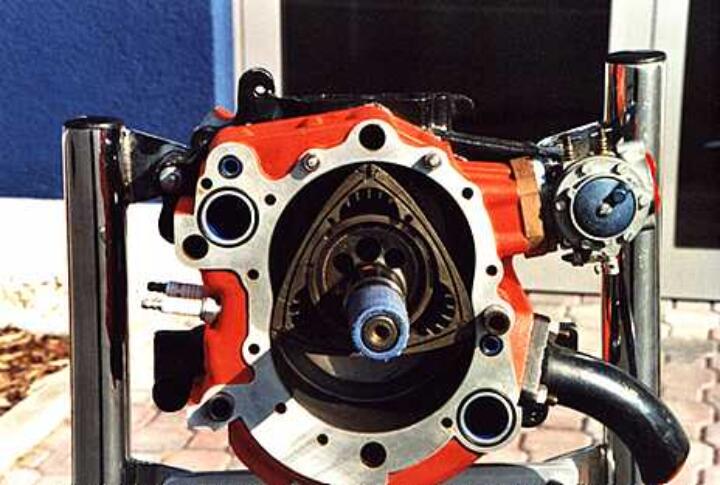

Wankel engine

Arguably the most commonly known alternative to the reciprocating engine is the rotary engine. Former car and motorcycle manufacturer NSU marketed Felix Wankel’s invention worldwide and engineered the Wankel Spyder and the NSU RO 80 as two proprietary models using rotary engines. More than 30 companies worldwide acquired licenses for the patent from NSU and subsequently from AUDI AG. From 1967 on, Mazda relied on the concept for decades and built more than two million rotary engines. However, due to reliability issues at the beginning of mass production, increasingly strict emission regulations, and the high consumption and low torque of this engine, it ultimately had no chance of success in the long run. As an extremely compact range extender in the spare wheel recess of the Audi A1 e-tron that was temporarily tested starting in 2011, the rotary engine was chanceless even as a complement to electrified powertrains in the recent past.

Propeller power

Completely forgotten today are propeller-powered cars from the 1920s of the past century. The French design Leyat Hélica had a huge propeller at the front, like a small airplane. Without a clutch, transmission and final drive the model saved some weight but the noise of the motor-driven propeller, the risk the rotor posed to other traffic participants as well as the delayed acceleration and difficult controllability prevented a wider spreading of such powertrains on the road. Other propeller-powered cars being tested were Traction Aérienne and Helicron. The Schlörwaren (pictured) that was unveiled as a research car at the IAA in 1939 – frequently dubbed “Göttingen egg” due to its aerodynamic shape (Cd 0.186!) – had a propeller drive flanged to it in 1942 as well. The design appearing equally monstrous and futuristic disappeared from the scene after a sensational test run in Göttingen. It was another concept that a propeller failed to help flying high.