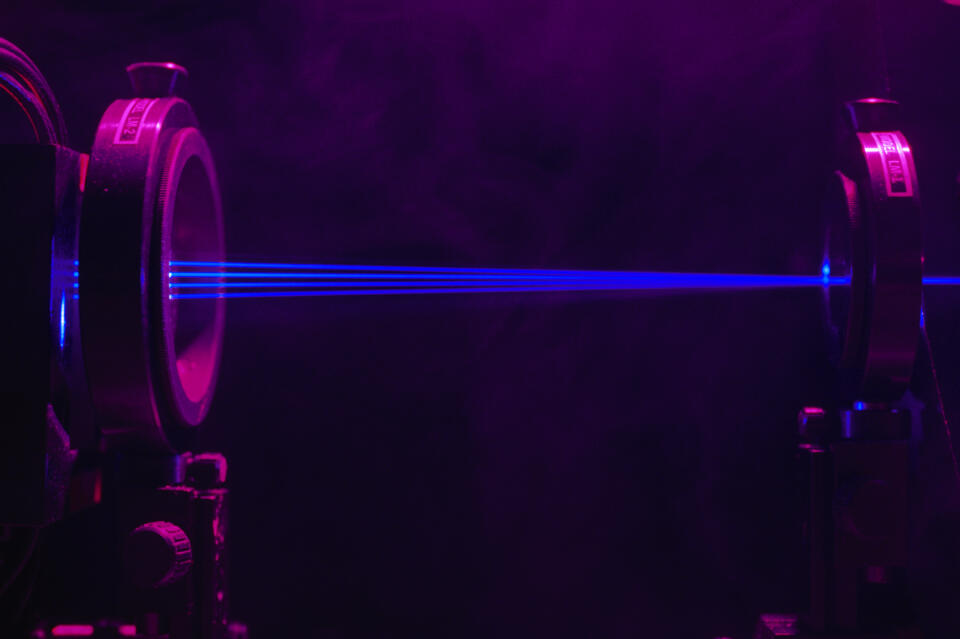

Light show

High-speed transistors

Complex simulations or processing of large data volumes require computing power of a magnitude that’s causing today’s computers to reach their limits. Responsible for the speed of computer operations are so-called field effect transistors (FETs). In order to become faster and faster, these transistors are becoming smaller and smaller so that as many of them as possible can be installed side by side. Current computers are already operating with impressive clock speeds of several gigahertz, in other words several billion computer operations per second. Latest-generation transistors have a size of merely 0.000005 millimeters (1.968503937e-7 inches) – that’s about the limit of their possible miniaturization and that’s where laser technology comes into play: In an experiment, scientists at Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) and the University of Rochester in New York have shown for the first time how signals can be transmitted via light waves instead of by electricity and transformers, and how computer operations using laser impulses could be executed up to one million times faster than before in this way. One oscillation of a light wave lasts only about one femtosecond equating to one millionth of one billionth second.

"At least we know that light wave electronics is possible in practice."

Tobias Boolakee, scientist at Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU)

“This is a great example of how fundamental science can lead to new technologies. We clarified the role of virtual and real charge carriers in laser-induced currents, and that opened the way to the creation of ultrafast logic gates,” said Ignacio Franco from the University of Rochester. Albeit: “It will probably be a very long time before this technique can be used in a computer chip, but at least we know that light wave electronics is practically possible,” Tobias Boolakee from FAU added.

You can find more detailed information on the topic here.

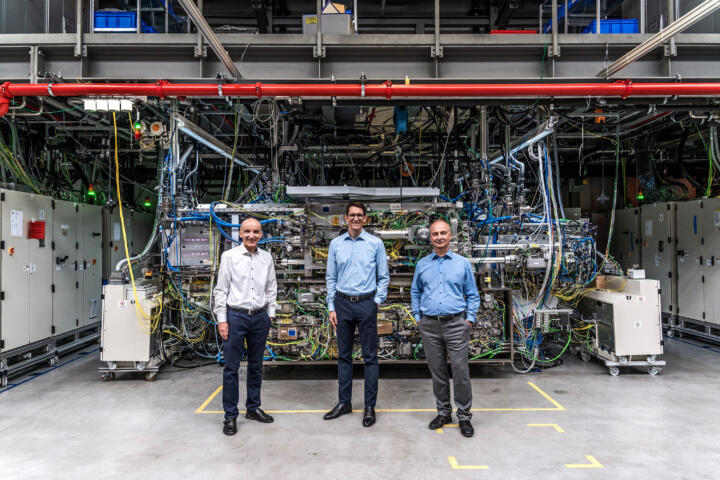

Fast chips

Another method to make computers faster by using lasers is extreme ultraviolet EUV) lithography. A chip, today, consists of billions of tiny structures created on thin silicon plates by means of ultraviolet light (UV). The larger the number of these structures on a chip the faster and higher its performance. However, this conventional method is increasingly reaching technical and economic limits but the limits of optics can be shifted by means of EUV lithography. The technique that has been developed by the Fraunhofer Institute for Applied Optics and Precision Engineering IOF together with companies such as Zeiss and Trumpf uses extreme ultraviolet, i.e., ultra-shortwave light (EUV) and sophisticated optical and mirror systems enabling even tinier structures. Whereas the conventional method uses light sources with a wavelength of 193 nanometers (7.5984e-6 inches) the new manufacturing method operates with merely 13.5 nanometers (5.31496e-7 inches). 1 nanometer is one millionth of one millimeter (0.03 inches). It takes very powerful lasers firing at tin droplets rushing past inside a vacuum chamber 50,000 times per second to generate a plasma flash of this wavelength. As a result, EUV lithography enables a more delicate resolution due to which chip manufacturers can produce smaller, faster and more powerful chips with manufacturing complexity and costs remaining within reason. By now, cell phones using chips produced with EUV light are available. Another field in which such high-performance chips might play an important role is autonomous driving because these chips are able to provide the system with the data required for driving safety at the requisite speed.