How ideas turn into success

Thinking outside the box

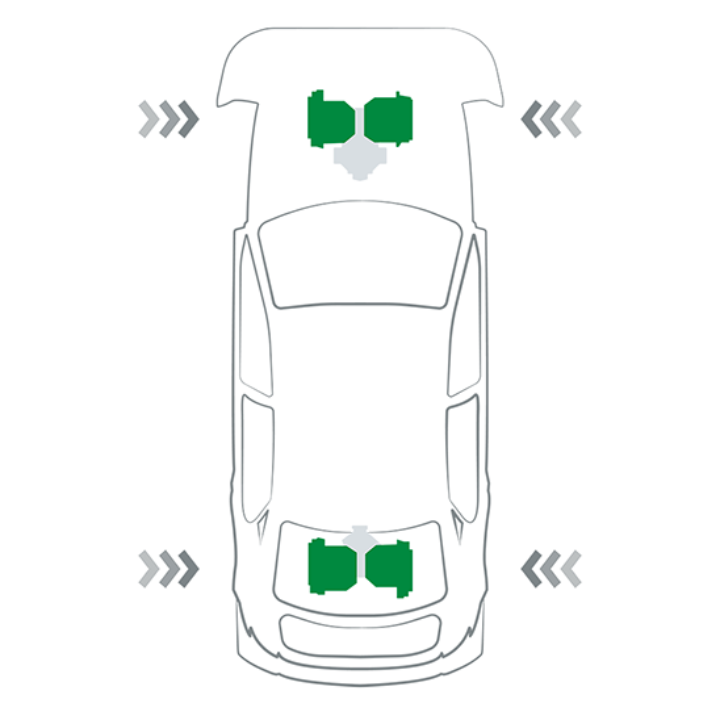

OmniSteer

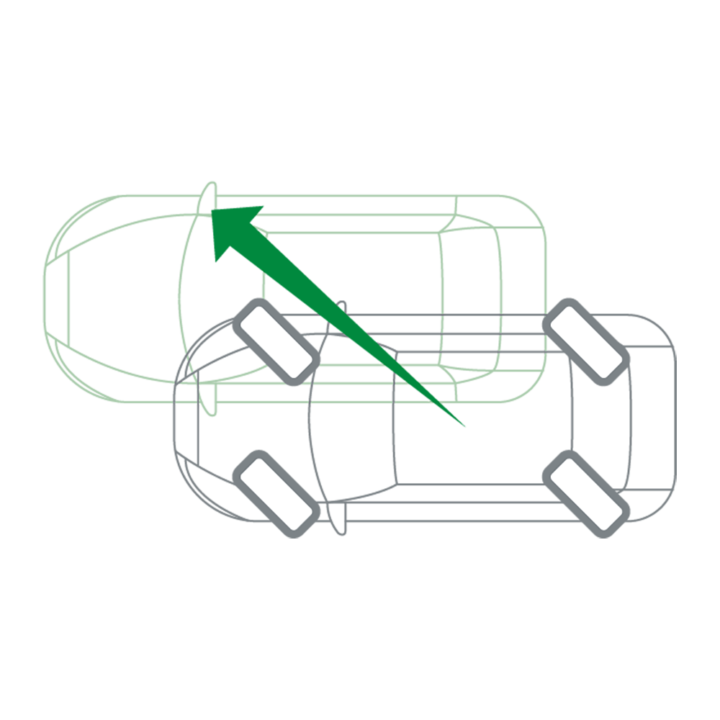

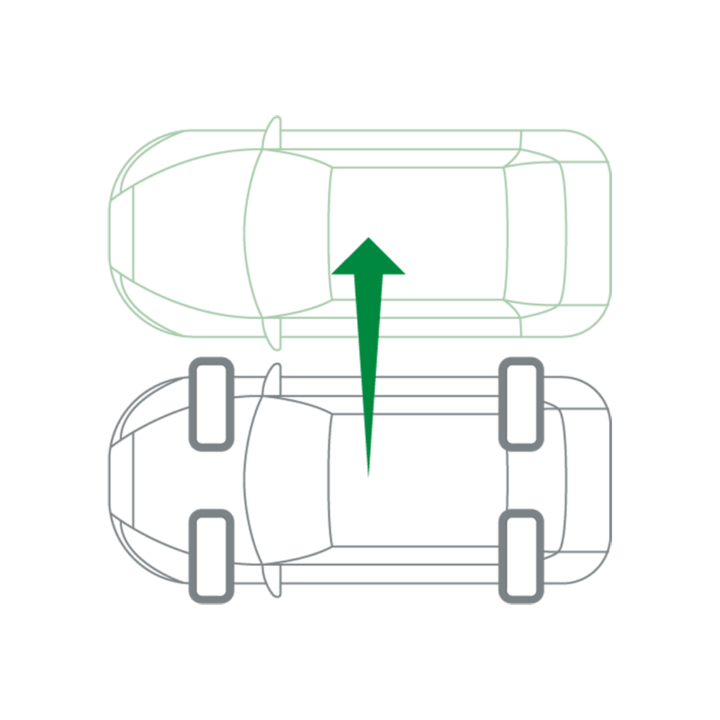

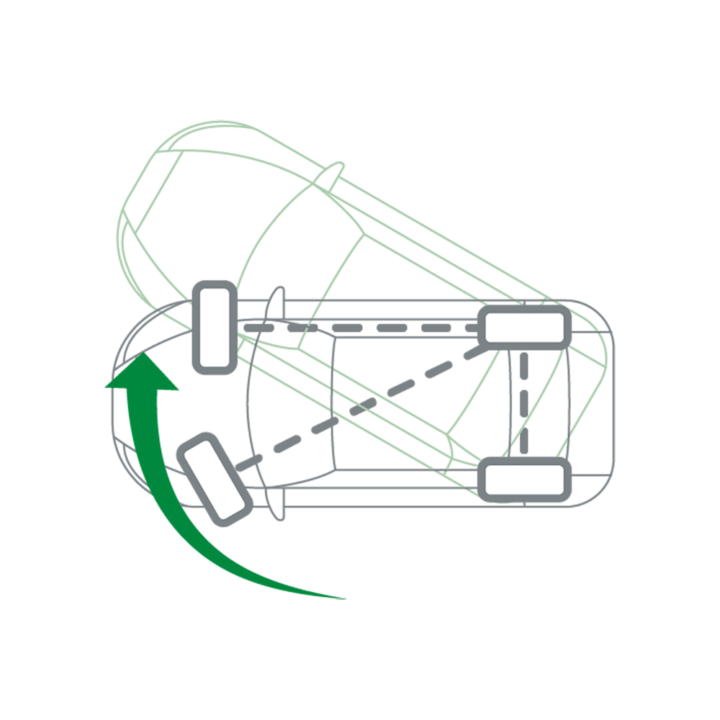

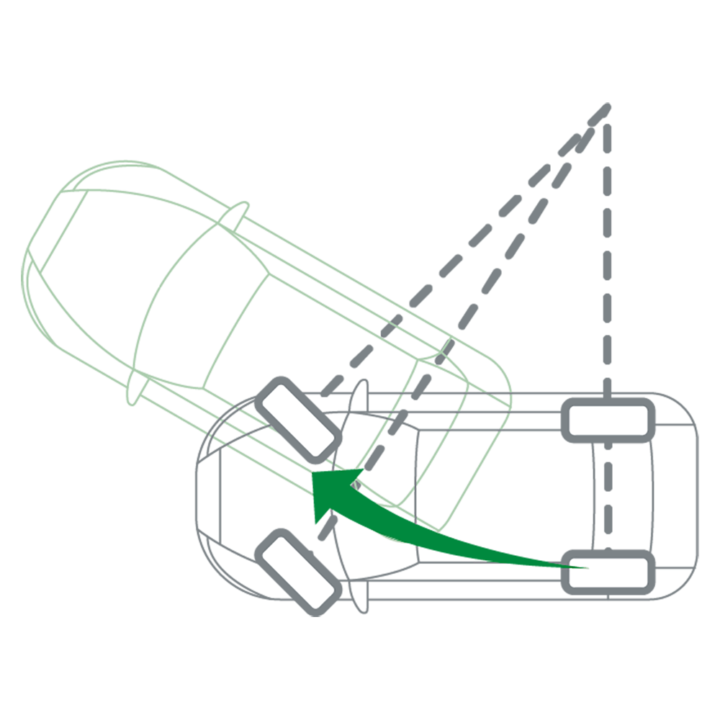

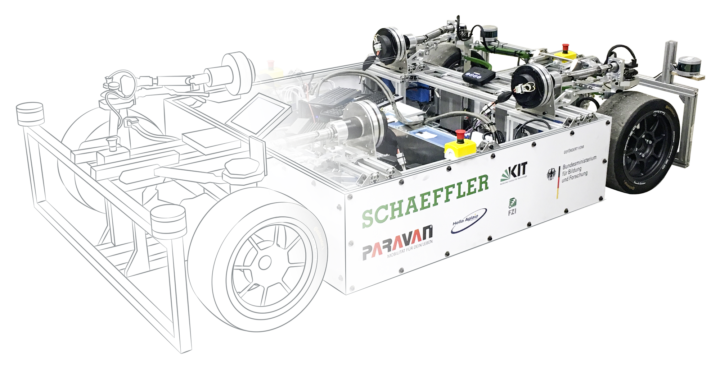

Mini soccer tables, guitars or small sailboats: an ordinary shoe box can be converted into all kinds of exciting things. Now the OmniSteer project proves that such a simple object as a cardboard box may even lay the foundation for successful innovations in a high-tech company. Together with several partners Schaeffler has developed a chassis system that paves the way for a new approach to urban mobility: parallel parking without stopping in the process – enabled by individually controllable wheels that are steerable up to a 90-degree angle. And the whole project started with a simple cardboard box.

The story of the OmniSteer project sounds like a modern fairytale, produced on the “stage of science” in a way that almost appears to have been choreographed in every detail – along the lines of “Once upon a time there was a shoe box …” In this case, though, reality surpassed the boldest research fantasies. “Starting with a cardboard box to which four servo motors were attached, we ultimately developed Schaeffler’s first self-driving vehicle,” says Prof. Dr.-Ing. Tim Hosenfeldt, Senior Vice President Technology Strategy and Innovation at Schaeffler. Now how did this come about?

The idea was inspired by the search for use cases for the wheel hub drive that Schaeffler had recently developed: Now wouldn’t it be a smart thing if vehicles were able to parallel park in one go in a fully automated process and without obstructing traffic? After all, every driver is familiar with the unnecessarily long lines of cars forming within seconds because someone in front is trying to squeeze their vehicle into a tight parking space.

Directed by Dr. Marcel Mayer, the first leader of OmniSteer, the project consortium received a 1.9-million euro grant from the German Federal Ministry of Education and Research. Mayer found powerful partners: Paravan GmbH, a specialist in accessible vehicle conversions with high expertise in steer-by-wire systems, HELLA Aglaia Mobile Vision GmbH (smart imaging software), and research teams from Karlsruhe Institute of Technology (KIT).

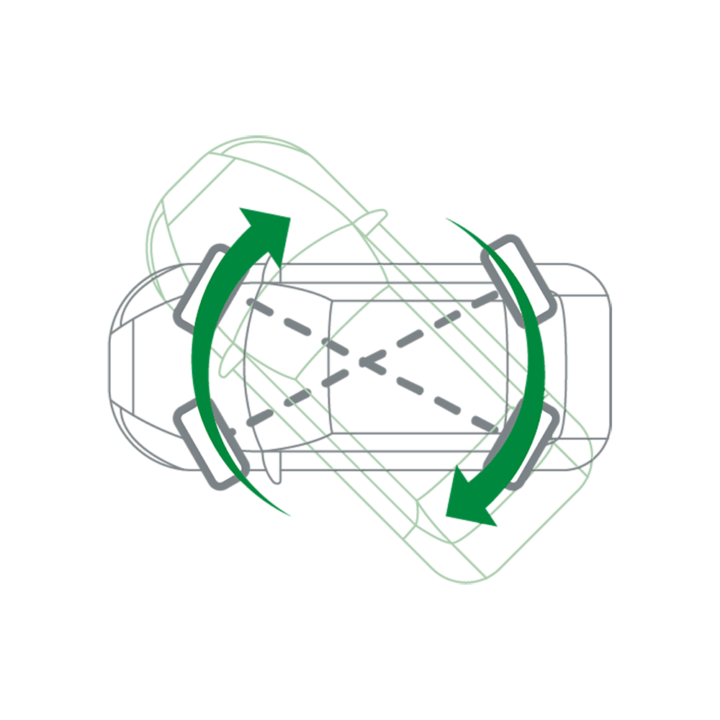

Based on the famous cardboard box mentioned above, the team initially designed “Oscar Junior,” a 1:5-scale prototype with environmental sensors and four corner modules. Subsequently, the “large” full-scale Oscar was created, a test vehicle that, thanks to its special kinematics with height-offset, steerable wishbones, boasts extreme agility – the kind of maneuverability that Schaeffler intends to incorporate in future Cargo and People Mover concepts, among other things.

A positive side effect of the project: Schaeffler has since entered into a joint venture with Paravan GmbH, plus former student employees involved in the OmniSteer project have since been hired by Schaeffler under permanent contracts. Dr. Ralf Stopp, Head of the SHARE (Schaeffler Hub for Automotive Research in E-Mobility) cooperation office at KIT, Philipp Kautzmann, Team Coordinator of the Automated Mobility Working Group, and Project Leader Dr. Paul Haiduk had joy about the successful project written all over their faces during the final presentation at the end of March.

“We’re going to make something that nobody has”

Torque Vectoring: wheel-selective control of engine torque

The humming of the electric race cars had gone silent, and the hustle and bustle of the Formula E circus in Hong Kong made way for the more relaxing part of the day. The late afternoon of October 8, 2016, is regarded as the time when the Schaeffler 4ePerformance was born – or at least the idea that was to turn into a technological adventure. In the pit lane, Audi driver Lucas di Grassi and Schaeffler’s Chief Technology Officer Prof. Peter Gutzmer talked about everything under the sun, including electric mobility, robocars, and their future. How could the subject be emotionally energized? How could people’s enthusiasm be inspired for it?

After a while, a somewhat far-out plan was formulated: “We’re going to make something that nobody has. We’re going to build the prototype of a super sports car to show that Schaeffler is able to deliver the total package for an electric four-wheel drive system.” The objective: learning the maximum from Formula E for a potential production application. Gutzmer: “Projects like the Schaeffler 4ePerformance accelerate the development of new technologies and particularly the buildup of expertise from the perspective of a whole vehicle, from packaging requirements to mechanical systems, from mechatronics and software applications to specific functions such as driving functions or cooling concepts.”

Seen in this light, it’s easy to understand why Schaeffler pushed such a challenging project so vigorously. Why else would anyone come up with the idea of installing four Formula E motors with real oomph (880 kW/1,200 hp in total) from the Audi Sport ABT Schaeffler race car into a vehicle that had never before existed in this form? Along the lines of something like: look how fast the magic of putting motorsport technology on the road can be performed. A car from the test lab – not a hermetically sealed laboratory – one that everyone is able to admire and that evokes emotions. An awe-inspiring laboratory.

So much for the idea, now let’s look at how it became reality: In an exchange with Dr. Simon Opel, who was in charge of Special Motorsport Projects at the time, a plan was forged and a team put together: 18 men and women in total. A young crew that was willing to walk the extra mile for the project. “Compliments to the team. Not once during the whole time did I hear them say, ‘We’re at our wits end.’ They always came up with solutions,” says Gutzmer. On board as partners were Schaeffler’s subsidiary Compact Dynamics (electric motors), Schaeffler Engineering (control units and software), ABT Sportsline (total vehicle bodywork) and Simon Opel’s motorsport team. The ambitious timeline from the initial idea to its implementation: one year.

An extremely short period of time, considering that the team was initially faced with a completely stripped-down Audi RS 3 LMS TCR race car, but the team worked hand in hand. Gutzmer: “The colleagues involved from the various technology units of the Schaeffler world gelled superbly. We generated a lot of knowledge and additional expertise during the project.” Torque vectoring, the wheel-selective control of engine torque, is just one of many examples.

The project resulted in a vehicle that utterly impresses, as Daniel Abt proved on setting his memorable world record of driving in reverse (210 km/h/130 mph). Lucas di Grassis’ text message sent to Peter Gutzmer after the first test drive was equally impressive testimony: “We made it, it’s outstanding!”

Dual vocational education

Dual System an export hit

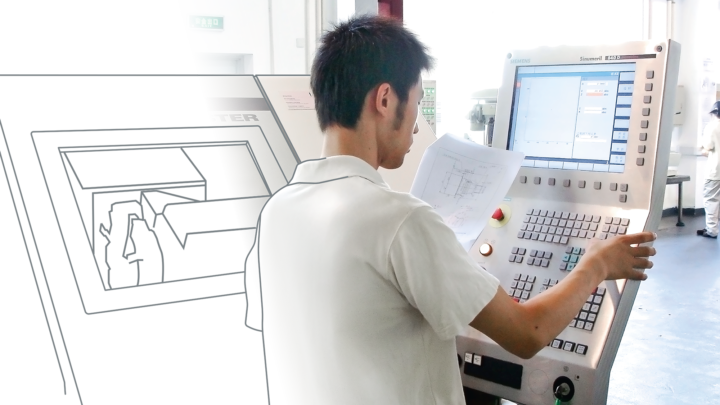

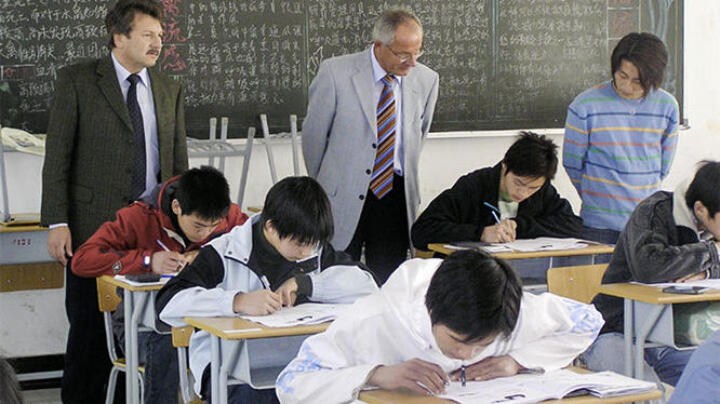

Squealing drills are eating their way through steel as thick as a thumb. Keeping an eagle eye on them, a lineup of trainers is watching the manual dexterity of their apprentices. Schaeffler continuously trains some 600 of them in China – in the same way apprentices have been trained in Germany for decades: one third of their time is spent in the classroom of a vocational school, two thirds at the company, the usual split. At the beginning of the 2000s, the situation in the Far East still looked different. Hiring skilled workers proved a real challenge. A needle in a haystack would have been easier to find. This prompted Schaeffler to export the proven German vocational education system.

At Schaeffler, mastering this massive challenge is closely linked to the name of a man who has since retired: former training manager Bernhard Schwab. Schwab recalls: “Actually, there was a lack of everything.” Hopelessly overcrowded vocational schools and ancient machines: rusty, defective, and hardly usable. Poorly trained trainers and a system in which apprentices were filled up to their ears with theoretical knowledge but hardly gathered any practical experience. Schwab: “The quality of the vocational training did not meet our requirements.”

However, in 2003, Schaeffler was in dire need of skilled workers in order to expand the plant in Taicang. Manufacturing operations were to be ramped up and a quick decision had to be made. Schwab and the then Chief Human Resources Officer Kurt Mirlach were in agreement that the situation called for a pragmatic approach, so they rented an old warehouse filled to the brim with all kinds of stuff and had modern CNC turning, milling and grinding machines – some of them from Germany – sent to the site. Schwab started meeting with government authorities and vocational schools, summoned two handfuls of trainers from Herzogenaurach to Taicang, and had courses in Chinese as well as acknowledged examinations of skilled workers developed in collaboration with the German Chamber of Commerce.

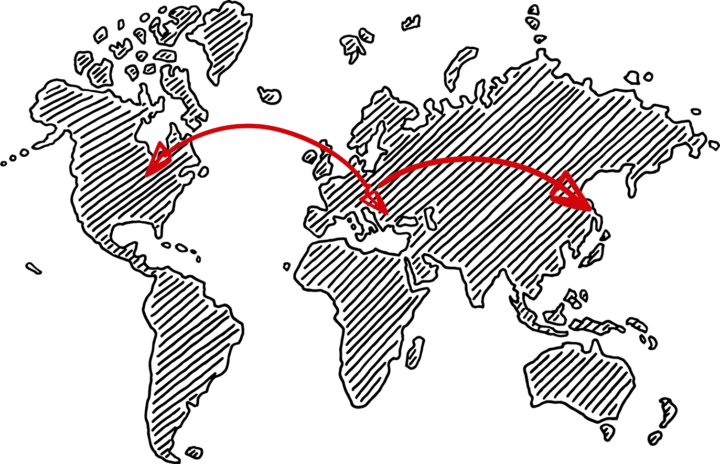

The whole project at times had a somewhat improvised character but that didn’t diminish its success. “Although we had interpreters a lot of the communication was done by using our hands and feet, plus translation computers,” says Schwab, looking back on those days with a smile. Practically from scratch, Schaeffler hired some 100 apprentices in 2003 – the beginning of a success story that Schaeffler has since continued in Mexico, Romania, and other places in the world. Especially in China, it also helped pave the way for other companies to train their own skilled staff. The vocational education program has seen its logical continuation in Schaeffler’s integrated degree program billed as “Two-in-One,” which has won several awards in China, including “Best Community Promoter” of the China Association of Enterprises with Foreign Investment (CAEFI).

Precise motion

Planetary screw drive

Planetary screw drive (PWG) – the name of this technical component doesn’t necessarily exude linguistic elegance nor suggests that it might be the basis of an exciting story about hospital beds, robots, and a Space Shuttle mission. But continue reading and find out how the PWG became part of the Schaeffler world.

A customer inquiry got the ball rolling: this is our problem, do you have an idea how to solve it? Business as usual at Schaeffler. Developing solutions on an equal footing with the customer. Customers have great confidence in the supplier’s development and manufacturing expertise. This particular case was about screw drives. Their performance limit had been reached in the customer’s application, so something new was needed: a powerful linear actuator, in other words a device that electromechanically moves a load on a straight line. The system was to be compact, powerful and – equally important – affordable.

This was by no means a challenge to be mastered in a snap. The road to the perfect solution was long. The project billed as “High-Performance-Smart-Actuator” began with market research because it was clear that an economically and technically feasible solution would not be achievable without the required production volumes. The results of the survey were extremely positive. More than 80 potential applications were identified for the new product: from riveting machines, plier welding heads, and clamping cylinders to hospital beds and dental chairs.

“We found that aesthetically appealing design plays an increasingly important role also for all kinds of technical devices,” explains Dietmar Rudy, Head of Product Development Linear Technology at Schaeffler. Clever solutions instead of clumsy technology monsters are in demand. This, however, means: “The drives must be so small that they invisibly blend with the structure. This only works with a small screw drive that, with low drive torques, is able to generate more axial force per available design space than previous systems,” says Rudy.

The development process began, initially with an industry comparison that included sectors such as aerospace. Now hadn’t there been a robot on board of a Space Shuttle in 1993 that performed complex assembly work with an extremely powerful electrical spindle system? Right! Rotex was the name of the robot that was able to do heavy-duty jobs using the previously mentioned planetary screw drive. Rudy: “Rotex’ motor system promised to meet all the key requirements.” The only disadvantage: “The space technology was far too costly for utilization on Earth.” The technical requirements were too high and the production volume too low in spite of the many fields of application. Fortunately, the know-how of diverse business divisions mesh like cogwheels at Schaeffler. In 2011, the Automotive Division was in search of a solution for a compact electromechanical clutch actuator and the Industrial Division shouted: Hello there, we’ve got something for you! The PWG. The integrative interaction produced the breakthrough. Due to the high-volume automotive production, the PWG for industrial applications can be offered at market price level. “The enormously large production volumes of these actuators made it possible for us to make the necessary investments in a reliable, non-cutting manufacturing process,” says Dietmar Rudy. Previously, costs had always been the impediment that kept the PWG from making its way into technical applications.